There are several advantages of titanium dental implants:

Biocompatibility: Titanium is a biocompatible material, meaning it is compatible with the human body. It does not cause any allergic reactions or adverse effects when placed in the jawbone.

Osseointegration: Titanium dental implants have the unique ability to fuse with the jawbone, a process called osseointegration. This provides a stable and strong foundation for artificial teeth, ensuring long-term stability.

Durability: Titanium is a highly durable material that is resistant to corrosion, wear, and tear. This makes titanium dental implants a long-lasting solution for missing teeth.

Aesthetics: Titanium dental implants are designed to closely mimic the natural tooth structure. They can be customized in size, shape, and color to match the surrounding teeth, resulting in a natural-looking smile.

Functional restoration: Titanium dental implants restore not only the appearance of missing teeth but also their functionality. They provide a secure base for artificial teeth, allowing patients to eat, speak, and smile confidently.

Minimal bone loss: Compared to other dental restoration options, titanium dental implants help preserve bone structure in the jaw. Since they fuse with the jawbone, they stimulate bone growth and prevent further bone loss.

Improved oral health: titanium dental implants do not require adjacent teeth to be modified or removed, unlike dental bridges or removable dentures. This helps maintain the overall oral health by preserving the natural teeth in the mouth.

Overall, titanium dental implants offer numerous advantages, making them a popular choice for dental restoration and tooth replacement.

Titanium dental implants are manufactured through a precise and systematic process that involves the following steps:

Assessment and Planning: Before the implant creation begins, a thorough examination of the patient's oral health and jaw structure is conducted. This assessment helps in determining the most suitable size, shape, and placement of the implant.

Implant Design: Based on the assessment, a custom implant design is created using specialized dental software. This design takes into account the individual's specific dental anatomy and ensures optimal implant positioning for long-term stability.

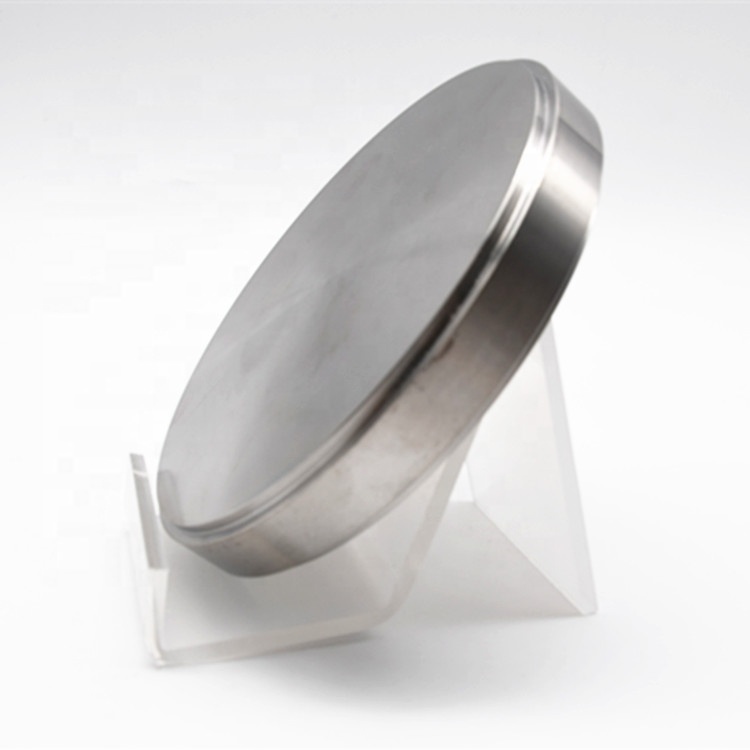

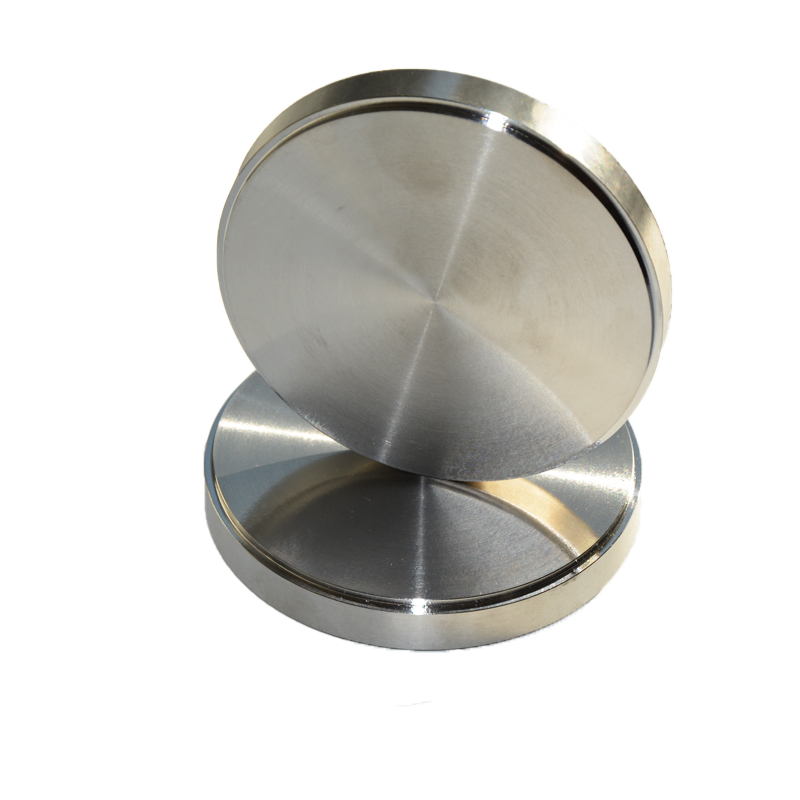

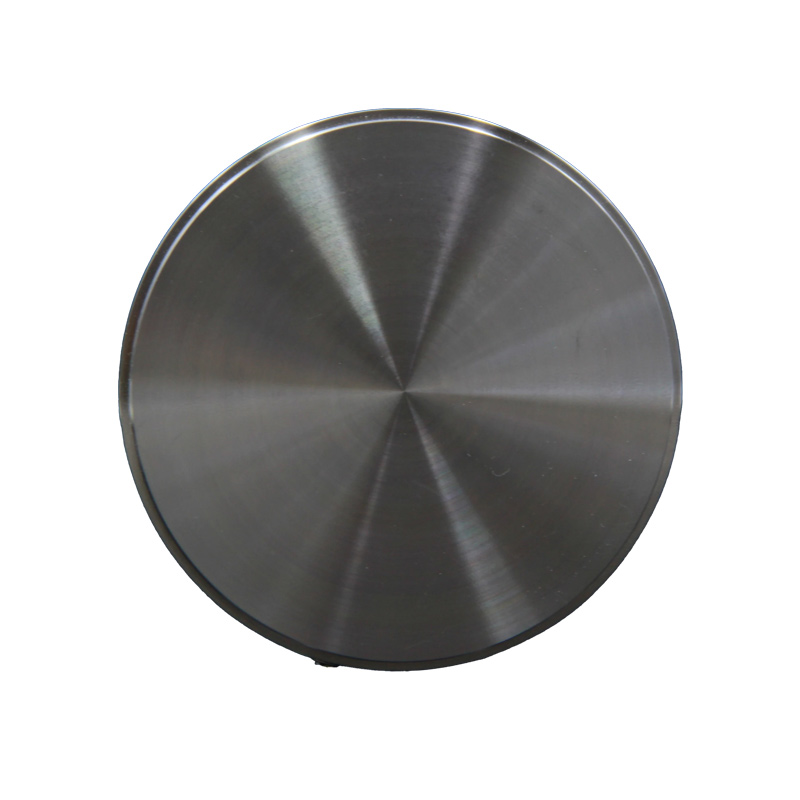

Titanium Alloy Preparation: Pure titanium or titanium alloys, known for their biocompatibility and strength, are selected as the primary materials. The raw titanium material undergoes a comprehensive sterilization process to ensure its purity and freedom from contaminants.

Milling or Casting: The titanium alloy is either milled or cast into the desired shape according to the implant design. Milling involves using computer-aided manufacturing (CAM) technology to precisely carve the implant from a solid titanium block. Casting utilizes a mold into which molten titanium is poured and allowed to solidify.

Surface Treatment: To enhance the integration of the implant with the surrounding bone, the surface of the titanium implant may undergo various treatments. Common techniques include acid etching, sandblasting, or plasma spraying, which roughen the surface to promote better osseointegration.

Quality Control: High-quality standards are maintained throughout the manufacturing process. Each implant undergoes rigorous inspection and testing to ensure its dimensional accuracy, structural integrity, and material purity.

Packaging: After passing the quality control checks, the implants are individually packaged in sterile containers, which protect them from contamination until they are ready for surgical placement.

It is important to note that the exact manufacturing process can vary depending on the dental implant manufacturer and their specific techniques. However, all processes aim to create durable and biocompatible titanium implants that effectively restore dental function and aesthetics.

Cases & Feedback

.jpg)