1. Product Introduction

Our dental milling burs are designed to be fully compatible with Amann Girrbach CAD/CAM systems. Whether you are working with zirconia, PMMA, wax, or other dental materials, these burs provide reliable performance and high precision. They fit perfectly with popular Amann Girrbach models such as Ceramill Motion 2 and Ceramill Mikro.

2. Main Features

Compatible with Amann Girrbach 4mm tool holder systems

High cutting precision for smooth and accurate results

Strong wear resistance for extended tool life

Low vibration and heat generation during milling

Suitable for multiple materials: zirconia, PMMA, wax, and more

3. Material and Coatings

Tungsten carbide core for strength and stability

Coating types:

DC / RC / DLC coating for zirconia

Diamond coating for glass ceramics

Uncoated burs for PMMA and wax

4. Available Sizes

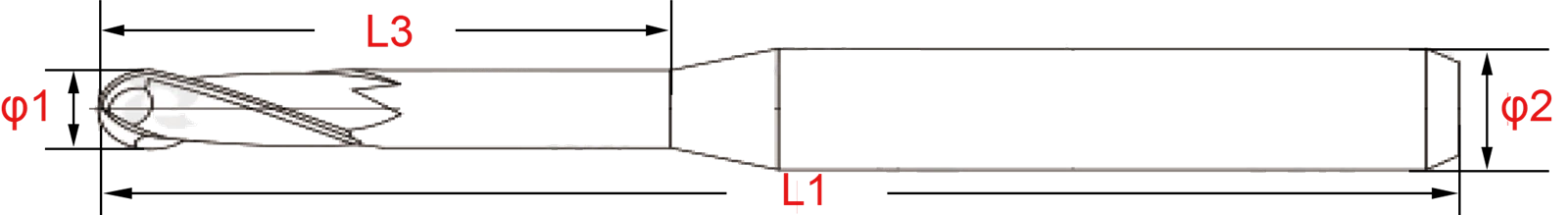

| Amann girrbach milling burs for Milling Zirconia | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 47 | 3 | DLC/RC/DC |

| 0.6 | 47 | 3 | DLC/RC/DC |

| 1.0 | 47 | 3 | DLC/RC/DC |

| 2.0 | 47 | 3 | DLC/RC/DC |

| 2.5 | 47 | 3 | DLC/RC/DC |

| Amann girrbach milling burs for Milling EMAX | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.4 | 47 | 3 | DC |

| 1.0 | 47 | 3 | DC |

| 1.4 | 47 | 3 | DC |

| 1.8 | 47 | 3 | DC |

| Amann girrbach milling burs for Milling PMMA | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.3 | 47 | 3 | / |

| 0.6 | 47 | 3 | / |

| 1.0 | 47 | 3 | / |

| 2.0 | 47 | 3 | / |

| 2.5 | 47 | 3 | / |

5. Application Scenarios

Milling zirconia crowns and bridges

Temporary restorations using PMMA or wax

Inlays, onlays, and abutments

Precision parts in dental CAD/CAM workflows

6. Cooperation Options

We support OEM/ODM and welcome distributors, dealers, and dental labs for long-term collaboration.

Services include:

Logo customization

Private label packaging

Sample support

Flexible bulk order terms

Looking for stable and high-performance milling burs for your Amann Girrbach system? Contact HONCHON today to get started.

.jpg)