1.product Introduction

Posterior multilayer block is a zirconia material used to make posterior molars. Posterior molars require materials with high hardness, good wear resistance and high safety performance. Posterior multilayer block can meet all these requirements and has a transparent color. Very good, with the same multi-dimensional gradient color as natural teeth. We are China's top zirconia factory, and our products are sold to all continents. We hope to become your long-term partner in China.

2.product Available size /color

open CADCAM system |

98*10mm,98*12mm 98*14mm 98*16mm 98*18mm 98*20mm 98*22mm 98*25mm 98*30mm |

| Zirkonzahn system | 95*10mm,95*12mm 95*14mm 95*16mm 95*18mm 95*20mm 95*22mm 95*25mm 95*30mm |

| Amann girhach system | 92*75*10mm,92*75*12mm 92*75*14mm 92*75*16mm 92*75*18mm 92*75*20mm 92*75*22mm 92*75*25mm 92*75*30mm |

| color | BL1 BL2 BL3 A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4 |

3.Product feature and application

Suitable for anterior and posterior restoration

A multilayer color gradient, strength gradient, translucency gradient, fracture gradient

High fracture toughness to resist chipping

4.Prodection details

Raw Material Preparation: High-quality Zirconia ceramic powder is selected as the raw material.

Molding: Zirconia powder is mixed with additives and pressed into blocks.

Sintering: The Zirconia blocks are sintered in a high-temperature furnace to achieve the desired hardness and density.

Multi-Layer Design: Different colors and translucencies of Zirconia are stacked and combined using precision machining techniques to create a multi-layered structure.

Shaping and Trimming: The multi-layered Zirconia material is shaped and trimmed according to specific dental restoration needs to fit the patient's oral condition.

Firing: The shaped Zirconia multi-layer blocks are fired in a kiln to ensure stability and durability.

Surface Finishing: The finished products undergo surface treatments such as polishing and coating to enhance their appearance and texture.

Quality Inspection: Strict quality inspections are conducted to ensure that each Zirconia multi-layer block meets standard requirements.

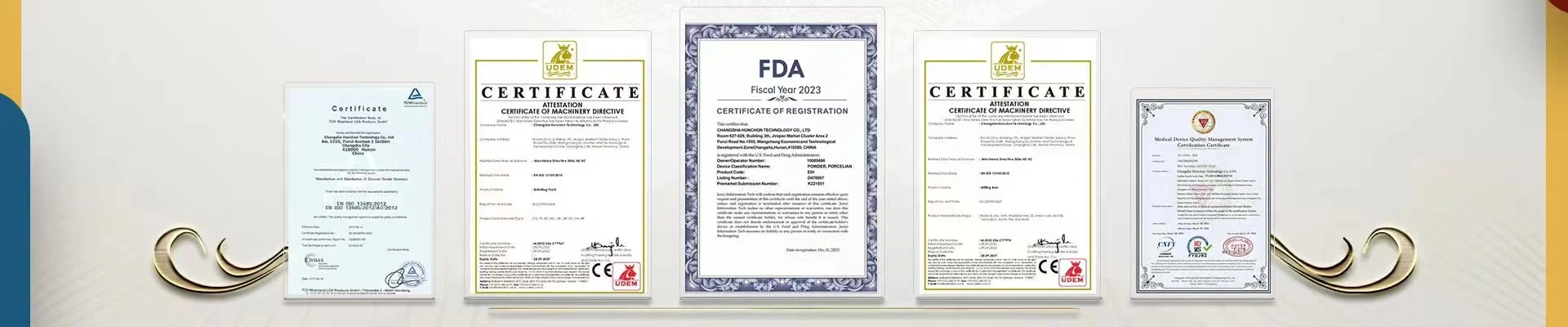

5.Prodect qualification

.jpg)