1.Introduction

In dental restoration work, precise and efficient processing equipment is key to ensuring restoration quality. HONCHON's five-axis fully automatic dental milling machine uses advanced technology and combines high performance with stability, making it the ideal choice for dental clinics and laboratories. This article will introduce the main features and scope of application of this equipment, as well as its advantages in actual work, to help you better understand its application value in daily processing.

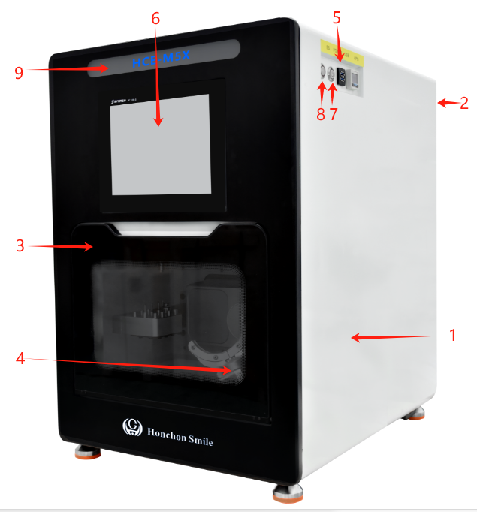

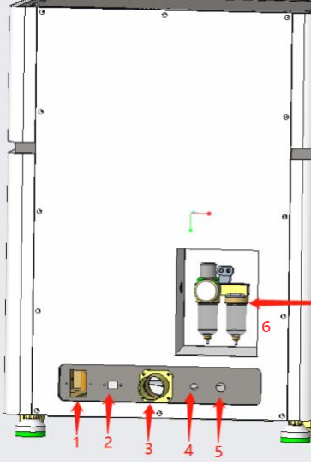

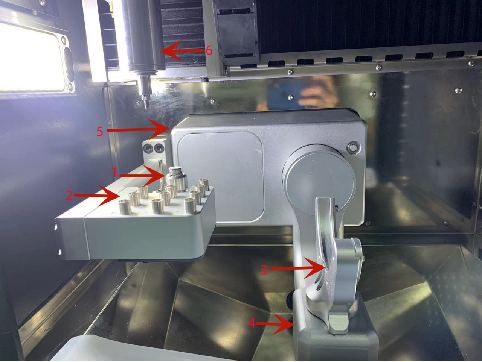

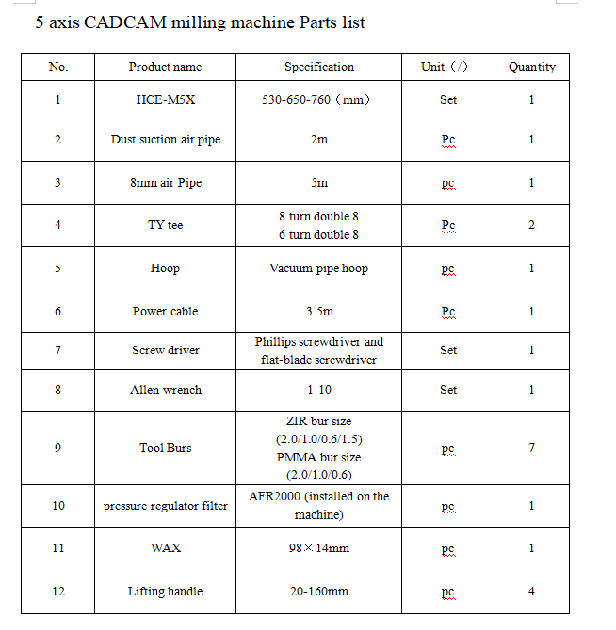

2. Product Structure Overview

|

|

|

|

|

|

3.Product Features

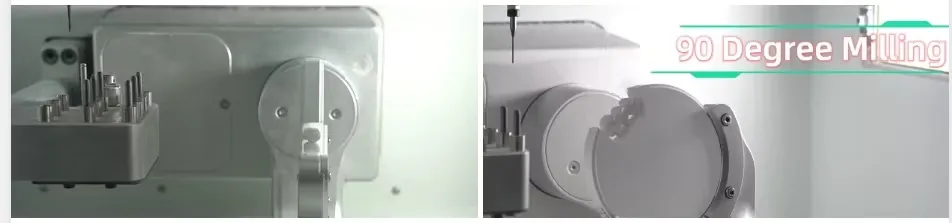

Five-axis milling design

Supports multi-angle, multi-directional precision machining, particularly suitable for complex restorations such as full crowns, bridges, sleeve crowns, veneers, implant abutments, denture models, and orthodontic brackets.

Fully Automatic Operation

After processing parameters are set, the equipment automatically completes the entire milling process, reducing manual intervention, improving efficiency, minimizing errors, and ensuring consistent restoration quality.

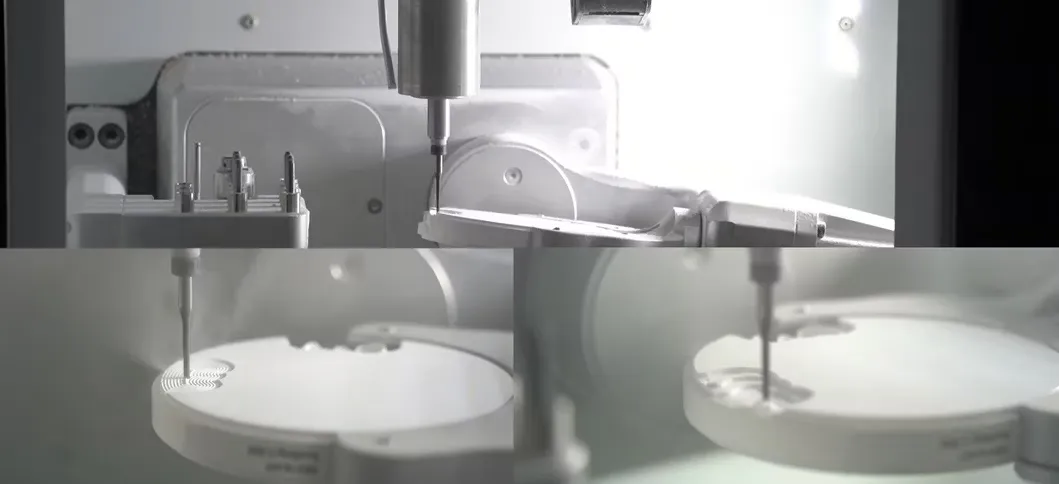

High-Precision Processing

Equipped with high-precision spindles and motion control systems, it achieves meticulous milling results, ensuring high restoration fit, enhancing patient comfort, and improving restoration outcomes.

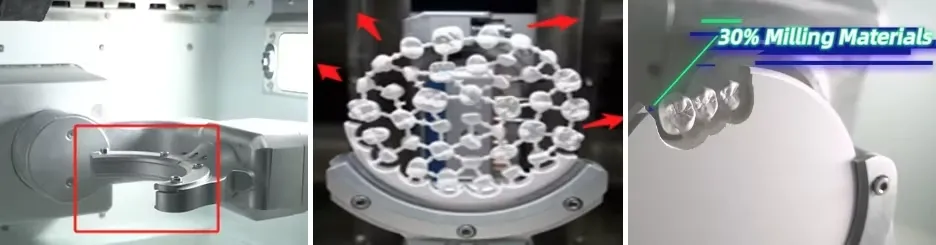

Robust Cutting Capability

Suitable for various common dental materials, including zirconia blocks, wax blocks, PEEK blocks, and PMMA blocks, with stable cutting performance and high efficiency.

4. Application Scenarios

Dental Restoration

Quickly and efficiently process single crowns, multi-unit bridges, and dentures, shortening the processing cycle and improving restoration efficiency and patient satisfaction.

Dental Laboratories

Supports high-precision batch processing, suitable for complex restoration designs, improving work efficiency and product consistency.

Dental Clinics

Fully automated and high-precision design enables clinics to complete restorations on-site quickly, reducing the number of patient follow-up visits and improving service quality.

5. Core Advantages

Highly flexible multi-angle processing

Meets various complex restoration needs

Improved productivity and efficiency

Fully automatic operation, 15 minutes for a single crown, 30 minutes for a three-unit bridge

High precision and stable quality

High processing precision, clear restoration edges, and reduced clinical adjustments

High compatibility and easy operation

Supports mainstream open source CAD/CAM systems, easy to learn and maintain

6. Why choose HONCHON (Changsha Honchon Technology Co., Ltd.)?

As a professional dental equipment manufacturer, HONCHON focuses on the research and development and production of high-performance dental milling equipment. We provide:

Stable and reliable equipment performance

Strong after-sales technical support

OEM/ODM customization service

Quick response customer service

Our five-axis milling machine has served many dental laboratories and clinics around the world and is deeply trusted.

Installation Requirements

Stable Voltage: 220–230V

Air Supply Pressure: ≥6.0 bar (stable)

Working Air Pressure: 4.5–7.5 bar (oil-free)

Operating Temperature: 15–35°C

Relative Humidity: <80%

Connectivity

USB/Ethernet: Rear USB port and network cable interface available

CAM Software Compatibility

Supports major CAM platforms such as Hyperdent and Millbox

Installation Procedure

Unboxing & Inspection

Carefully unpack the machine and verify that all accessories and components are included.Power Connection

Connect the machine to a stable 220V power supply.Air Supply Connection

Connect the unit to an air compressor that meets the required pressure range.Dust Extractor Connection

Attach the dust extractor to the designated port.Vacuum Hose & Linkage Line

Connect both the vacuum hose and linkage line to the dust extraction system.Bur Installation

Insert and secure the milling burs into the spindle/tool magazine.Software Installation

Install the provided CAM software on your computer. Follow the setup instructions for proper configuration.

7.Contact Information

- Phone: +8613055185196

- WhatsApp: +8613055185196

- Email: luis@honchon.com

8. (FAQ) – HONCHON 5-Axis Dental Milling Machine

1. What experience does HONCHON have in the dental milling machine industry?

The HONCHON SMILE brand has been dedicated to the dental field for 16 years, with extensive customer service and technical expertise. Our 5-axis fully automatic dental milling machine has been on the market for three years, has been widely validated by the market, has a good reputation, and is highly recognized by domestic and international customers.

2. What is the price of HONCHON's 5-axis milling machine? How cost-effective is it?

Our 5-axis dry milling machine is priced at USD 13,600, significantly lower than the prices of mainstream brands on the market (USD 50,000–100,000). We provide customers with high-precision, high-efficiency professional equipment at a more reasonable cost, offering outstanding cost-effectiveness.

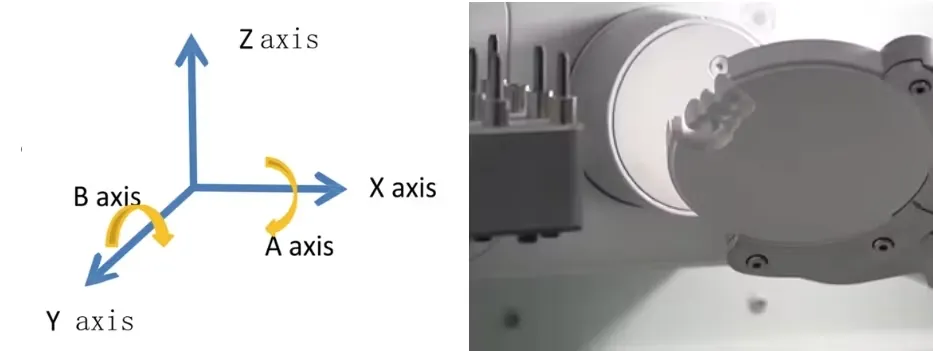

3. Is your milling machine truly 5-axis interaction?

Yes, HONCHON's model is a true 5-axis interaction milling machine.

The A-axis can rotate continuously at 360°

The B-axis can swing at a large angle between 30° and 90°

This design supports precise processing of complex dental restorations, particularly suitable for structures such as bridges, crowns, and implant restorations with complex geometries.

4. How long does it take to mill a single crown?

Under standard conditions, our equipment can mill a single crown in approximately 12 minutes, offering high speed and efficiency, making it ideal for chairside restorations and other scenarios with strict time constraints.

5. What is the warranty policy and after-sales service like?

We offer a one-year warranty for the entire machine. During the warranty period, all component issues can be replaced free of charge.

Additionally, we have a team of professional after-sales engineers available 24/7 online, providing free remote troubleshooting, usage training, and technical guidance services to ensure a worry-free user experience.

.jpg)