Product Overview

Our Imes-icore compatible milling burs are designed for high-precision dental CAD/CAM systems, including CORiTEC One, 250i, 350i, and 650i series. These burs can be used for milling zirconia, titanium, PMMA, wax, and glass ceramics, and are well-suited for both dental labs and clinics.

They help produce clean, accurate restorations—whether it’s a single crown or a full-arch bridge.

Key Features

Perfect Compatibility

Fully compatible with popular Imes-icore milling machines.High Precision

Sharp cutting edges for smooth, clean results.Long Tool Life

Made from high-quality tungsten carbide and coated for durability.Various Coating Options

RC, DC, DLC, and Diamond coatings for different material needs.Stable Milling Performance

Reduced vibration and less heat during operation.

Tool Types & Applications

| Tool Type | Milling Material | Coating Type | Use Example |

|---|---|---|---|

| Zirconia Bur | Pre-sintered Zirconia | RC / DLC / DC | Crown, coping, bridge |

| Metal Bur | Titanium, Cobalt-Chrome | DLC / RC | Implant parts, custom abutments |

| PMMA Bur | PMMA, Wax | No Coating | Temporary crowns, models |

| Glass Ceramic Bur | Lithium Disilicate | Diamond Coated | Veneers, inlays, fine restorations |

Standard Sizes

| Diameter | Application |

|---|---|

| 0.6 mm | Fine detailing |

| 1.0 mm | General use |

| 2.5 mm | Rough milling |

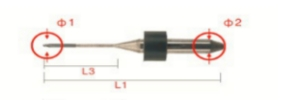

| CADCAM System | Function | Coating | Shaft Φ2/mm | Total Length L1/mm | headmeter Size/Φ1mm | ||

| Round | Flat | Toric | |||||

| Imes Icore | Milling Zirconia | DLC/RC/DC | Φ3mm | 48 | 2.5/1.0/0.6/2.0/1.5 | / | / |

| DLC/RC/DC | Φ6mm | 50 | 2.5/1.0/0.6 | / | / | ||

| Milling Emax | DC | Φ3mm | 40 | 2.5/1.0/0.6 | / | / | |

| Φ6mm | 40/50 | 2.5/1.0/0.6 | / | / | |||

| Miling Metal | / | Φ6mm | 50 | 3.0/2.0/1.0/1.5/0.6 | 1.0/2.0/1.5 | 2.0 R0.2/ 1.5 R0.1/ 1.5R0.2 | |

| / | Φ3mm | 3.0/2.0/1.0 | |||||

| Milling PMMA | / | Φ3mm | 48 | 2.5/1.0/0.6/2.0/1.5 | / | / | |

| / | Φ6mm | 50 | 2.5/1.0/0.6 | / | / | ||

Other sizes and special shapes can be customized based on your needs.

Compatible Imes-icore Models

CORiTEC One

CORiTEC 150i

CORiTEC 250i series

CORiTEC 350i / 350i PRO+

CORiTEC 650i / 650i Loader

Both wet and dry milling options supported.

Order & Service

MOQ: 10 pcs

Sample: Available on request

Lead time: 3–5 business days (in stock)

OEM/ODM: Logo engraving, packaging, and coating customization supported

Why Choose Us?

Over 10 years of dental milling tool production

Factory-direct, fast delivery, stable quality

Professional after-sales support

Affordable price without compromising performance

Contact Information

Email: luis@honchon.com

Website: www.honchon.com

Need help selecting the right burs for your system? Our team is happy to assist.

.jpg)