1. Cylinder-Shaped Grinding Tools (Top Row)

Grit: Fine

Models: TG01, TG02, TG03, TG06, TG07

Description: These slim cylindrical or tapered tools are designed for precision diamond grinding for zirconia, suitable for contouring and shaping.

Speed: 8000–15000 rpm (Max 25000 rpm)

Packaging: 1 piece per pack

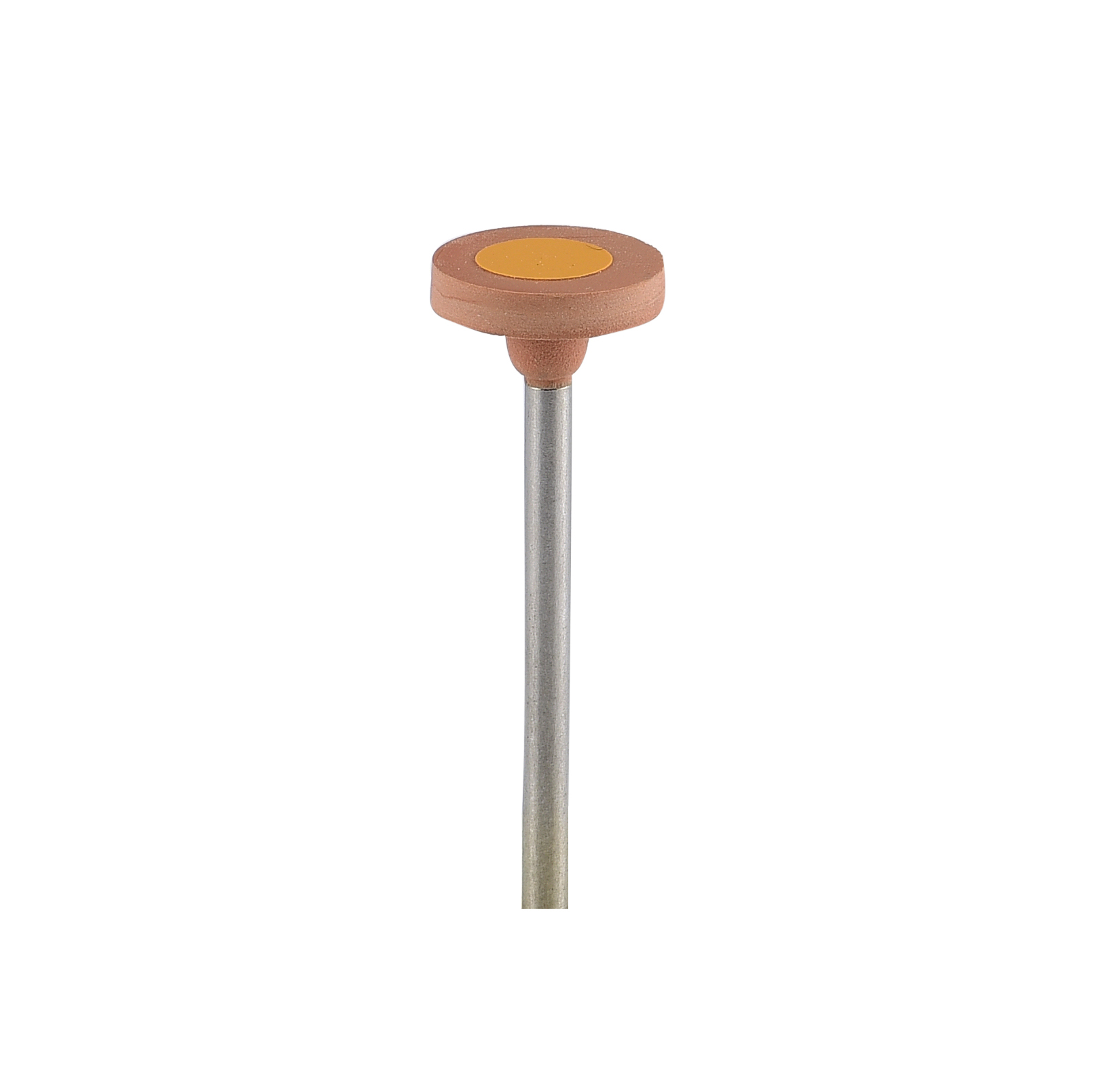

2. Flat Disc-Shaped Grinding Tools (Second Row)

Grit: Fine

Models: TG08, TG09, TG10, TG11, TG12

Description: Ideal for surface grinding of zirconia, these flat discs ensure smooth, controlled diamond grinding for zirconia restorations.

Speed: 8000–15000 rpm (Max 25000 rpm)

Packaging: 1 piece per pack

3. Extra-Fine Grinding Tools (Third Row)

Grit: Extra Fine

Models: TF10, TF02, TF03

Description: Designed for the final stage of diamond grinding for zirconia, these tools allow precise finishing with minimal surface damage.

Speed: 8000–15000 rpm (Max 25000 rpm)

Packaging: 1 piece per pack

4. Polishing & Contouring Tools (Bottom Row)

Grit: Fine

Models: HT07C, HT06C, HT10C, HT67C

Description: These tools combine contouring and polishing in the diamond grinding for zirconia process. Useful in fine adjustments and high-touch areas.

Speed: 8000–15000 rpm (Max 25000 rpm)

Packaging: 1 piece per pack

This page mainly introduces our factory's diamond grinding for zirconia. Diamond grinding for zirconia (diamond grinding tools for zirconia) is divided into four subcategories, which are designed based on different usage scenarios, shape structures, and processing requirements. The specific classification reasons are as follows:

1. Based on Shape—To Match Different Grinding Areas and Angles

Each tool has a unique shape designed for specific applications:

Cylindrical/tapered heads: Ideal for internal surfaces, margins, and detailed contouring.

Flat disc shapes: Perfect for working on broad, flat surfaces of zirconia restorations.

Pointed or cone shapes: Designed for occlusal anatomy, grooves, and contact areas.

Special geometries: Increase surface contact or meet specialized shaping needs.

Purpose: These variations allow technicians to grind zirconia restorations from all angles with precision and efficiency.

2. Based on Grit Size—To Control the Stage and Smoothness of Grinding

Fine grit: Used for initial contouring and trimming without damaging the surface.

Extra-fine grit: Used for pre-polishing or final refinement before actual polishing.

Purpose: Layered use of different grit levels ensures a smooth surface finish and accurate shape without chipping or overheating zirconia.

3. Based on Tool Dimensions—To Fit Various Handpieces and Clinical Needs

Sizes vary to ensure compatibility with dental lab equipment and to allow fine control in both large restorations and intricate areas.

Purpose: Matching size to task improves working efficiency and safety.

.jpg)