Super translucent zirconia block production process and precautions

2025-09-08

Introduction

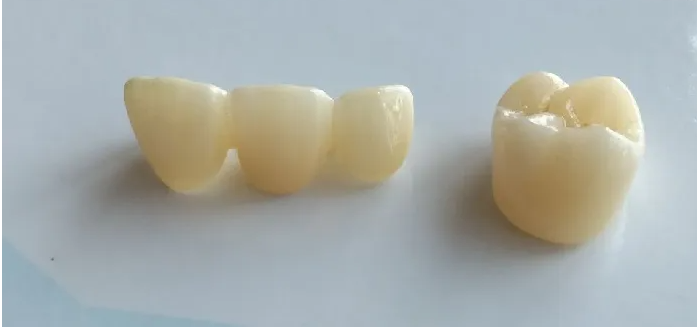

Super translucent zirconia blocks are widely recognized in modern dentistry for their combination of high translucency, superior strength, and durability. As a leading China-based super translucent zirconia block manufacturer, supplier, and wholesale factory, HONCHON specializes in producing premium zirconia blocks suitable for crowns, bridges, veneers, and implant-supported restorations. The production process is carefully controlled to ensure each block meets the highest standards of biocompatibility, aesthetics, and mechanical performance.

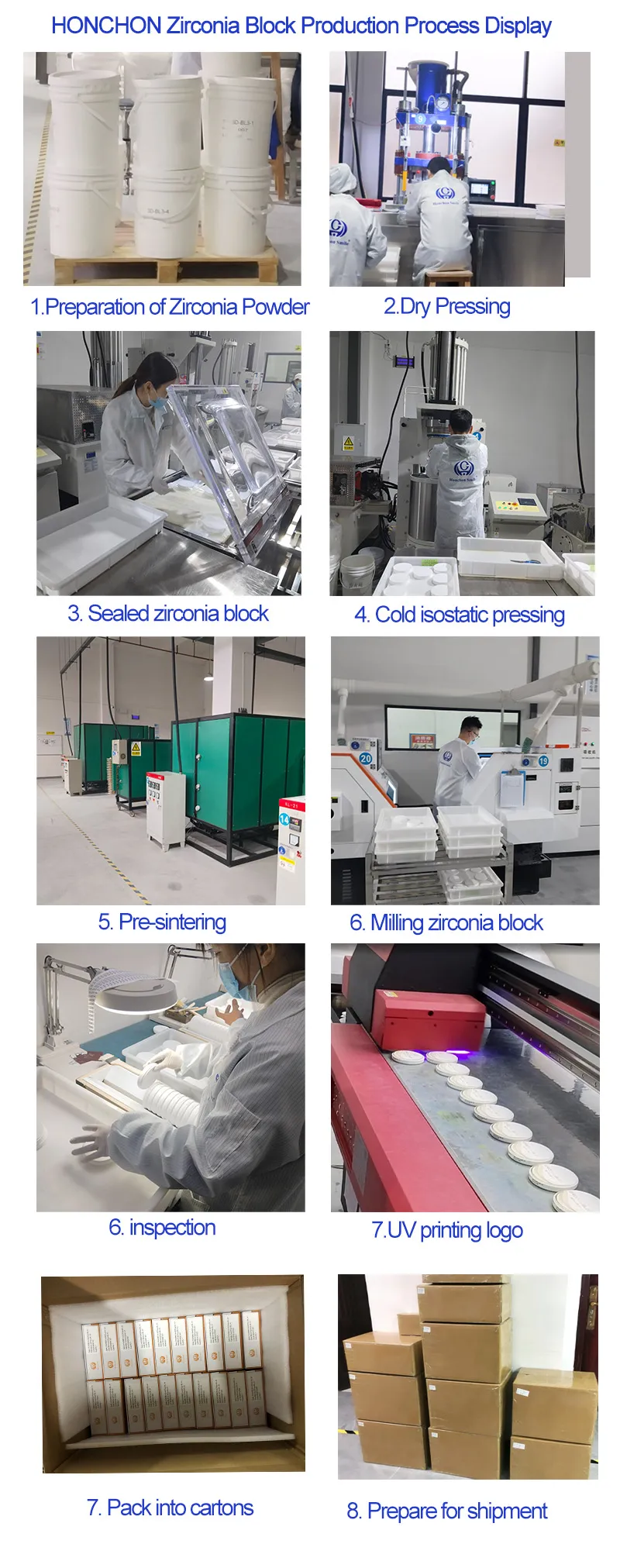

Key Steps in Super Translucent Zirconia Block Production

1. Selection of High-Quality Raw Materials

The production begins with sourcing premium zirconium dioxide (ZrO₂) powders. Raw materials are carefully selected to ensure they are free from impurities, which is critical for achieving consistent translucency, strength, and durability in the final zirconia blocks.

2. Powder Preparation

Selected zirconia powders are processed into fine, uniform particles. Accurate measurement and mixing of the powders guarantee consistent density and color throughout the blocks, which is essential for both aesthetic and structural performance.

3. Precision Milling

The prepared powders are milled to achieve uniform particle distribution. Proper milling ensures the blocks have the required mechanical strength and translucent appearance, providing optimal results for dental restorations.

4. Sintering

Milled zirconia powders are pressed into molds and subjected to high-temperature sintering. This process densifies the material, enhancing strength, hardness, and translucency. Proper sintering is critical to prevent defects such as cracking or warping, ensuring reliable and durable restorations.

5. Finishing

After sintering, the zirconia blocks undergo finishing processes including polishing, shaping, and cleaning. This step ensures that each block meets quality standards for dimensional accuracy, translucency, and surface smoothness, making them ready for CAD/CAM milling in dental laboratories.

Quality Control and Precautions

To maintain high standards, several precautions are strictly observed during production:

Controlled Environment: Temperature, pressure, and humidity are monitored to maintain ideal production conditions.

Raw Material Inspection: Regular checks ensure powders are free from contaminants.

Equipment Calibration: Milling and sintering machines are regularly calibrated to achieve consistent quality.

Proper Handling and Storage: Finished zirconia blocks are carefully stored to prevent damage or contamination before shipment.

Why Choose HONCHON Super Translucent Zirconia Blocks?

China Manufacturer & Factory: Over a decade of experience in producing high-quality dental zirconia blocks.

Wholesale Supply: Large-scale production ensures reliable and timely delivery.

Premium Material: High-purity zirconia powder ensures exceptional translucency, strength, and biocompatibility.

CAD/CAM Compatible: Fully compatible with digital dentistry workflows, ensuring precise restorations.

OEM & Customization: Supports custom shading and sizing to meet dental lab and clinic requirements.

Conclusion

The production of super translucent zirconia blocks is a highly sophisticated process requiring precision, strict quality control, and advanced manufacturing techniques. By sourcing the best materials and carefully controlling every production step, HONCHON ensures dental professionals receive zirconia blocks that excel in translucency, strength, durability, and biocompatibility.

As a leading China manufacturer, supplier, and wholesale factory of super translucent zirconia blocks, HONCHON is committed to providing high-quality dental materials that enhance patient outcomes and streamline the workflow for dental laboratories and clinics worldwide.

Contact HONCHON today to learn more about our super translucent zirconia blocks and how they can improve your dental restorations.