Zirconia Blocks: From Factory to Dental Practice

2025-09-18

Introduction

Zirconia blocks have become a key material in restorative dentistry. Their strength, translucency, and biocompatibility make them ideal for crowns, bridges, and implant restorations. However, achieving reliable results depends on both the material quality and the choice of manufacturer.

This guide covers the complete journey of zirconia blocks—from production to chairside application—helping dental labs and clinics select the right partner for consistent results.

Manufacturing Process

1. Premium Raw Materials

High-grade zirconium dioxide powder is the foundation. Stabilizers like yttrium oxide enhance toughness and translucency. Top factories, such as HONCHON, source powders from Tosoh (Japan) and Sinocera (China) to ensure uniformity and purity.

2. Cold Isostatic Pressing

The powder is compacted under high pressure to form a dense green body. This step ensures structural stability and consistent milling performance.

3. Pre-Sintering

Blocks undergo partial sintering, achieving machinable hardness without compromising accuracy.

4. Final Sintering

Milled restorations are fully sintered at high temperatures (up to 1500°C) to achieve final density, translucency, and mechanical properties.

5. Quality Control

Certified factories conduct rigorous testing, including density checks, bending strength, and translucency assessments. ISO 13485 compliance and FDA registration ensure clinical-grade performance.

Selecting a Manufacturer

When evaluating zirconia suppliers, consider:

Material Quality: Consistent color, uniform grain, and reliable flexural strength.

Certifications: ISO 13485, FDA registration.

Supply Reliability: Stable inventory, short lead times, and scalable production.

Technical Support: Milling guidelines, sintering curves, and after-sales assistance.

OEM/ODM Flexibility: Pre-shaded blocks, multilayer designs, and private labeling.

Tip: Don’t focus solely on price—assess overall value, including logistics, support, and customization options.

Logistics: Factory to Dental Practice

Reliable suppliers maintain a controlled supply chain:

Protective Packaging: Foam inserts or vacuum-sealed boxes prevent damage.

Global Shipping: Air or sea freight depending on urgency and order volume.

Fast Delivery: Top suppliers, like HONCHON, can dispatch standard orders within 1–3 days.

Application in Dental Labs

Zirconia blocks integrate with CAD/CAM workflows:

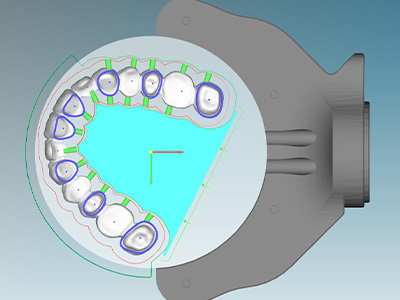

Digital Design: Restorations modeled from patient scans.

Milling: Blocks shaped precisely into crowns, bridges, or implants.

Final Sintering: Achieves full density and final shade.

Finishing: Staining, glazing, and polishing for esthetics.

Delivery: Restorations seated for strength, durability, and natural appearance.

High-quality zirconia reduces chipping, ensures esthetic results, and improves patient satisfaction.

Why HONCHON

HONCHON is among China’s top zirconia block manufacturers, offering:

Comprehensive Product Range: HT, ST, UT, multilayer, and pre-shaded blocks.

System Compatibility: 98mm, 95mm, 92×75.

Certifications: ISO 13485, FDA registered.

High Production Capacity: 100,000 blocks/month.

Customization & OEM Services: Shade development and private labeling.

After-Sales Assurance: 5-year warranty with full batch traceability.

HONCHON combines factory-direct pricing with consistent quality, making it a reliable partner for dental labs worldwide.

Conclusion

From raw materials to patient-ready restorations, the journey of zirconia blocks is critical to clinical success. While international brands set high benchmarks, HONCHON provides a competitive alternative—combining quality, flexibility, and efficient supply. By selecting a trusted manufacturer, dental labs and clinics can ensure superior restorations, smooth workflows, and satisfied patients.