How to Choose the Right Dental Zirconia Blocks for Dental Labs

2025-06-11

As the most commonly used material in dental restorations, dental zirconia blocks have become an important choice for dental laboratories to fabricate crowns and bridges due to their high strength, beauty,, and durability. How to select the right zirconia block to ensure the quality of restorations and processing efficiency is a serious consideration for every dental laboratory owner or purchasing staff when facing the diverse zirconia products in the market.

In this article, we will combine material properties, quality standards, system compatibility,, and practical advice to provide you with a comprehensive selection reference.

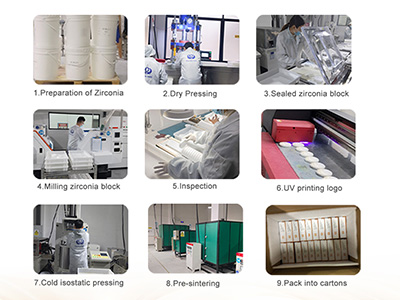

1.Material quality and composition

When choosing the right dental zirconia block, high-quality raw material is the foundation.

High-purity zirconia: Take the Chinese market as an example; the current mainstream dental powder is mainly based on Japanese Toso powder, Shandong Guocera material, etc. Japanese powder is more expensive; many domestic dental manufacturers will purchase high-quality powder produced by Shandong Guocera material, which can nsure that the strength and transparency of the material reachhe best state.

Low impurity content: impurities will affect the mechanical properties and aesthetic effect of zirconia, so preference should be given to products with stable quality and very few impurities.

Compliance certification: all purchasers in the procurement of sample orders, be sure to confirm with the manufacturer he validity of CE and FDA. With the advancement of the EU MDR regulations, now CE is is officially in the new certificate and the old certificate of the alternation stage. Be sure to ensure that the product has ISO 13485, CE, FDA,, and other international certifications n behalf of the manufacturing process in line with the strict quality standards of medical devices.

2. Selection of zirconia block types

Different types of zirconia blocks are selected according to the repair needs:

White zirconia blocks

White zirconia blocks are currently circulating in the Middle East, Southeast Asia,, and other less developed regions. White zirconia blocks need to be subsequently dyed, which is suitable for laboratories pursuing personalized customization.

Pre-colored zirconia blocks

Pre-colored zirconia blocks are the mainstream products in the market at present, with very high cost performance. The color of pre-colored zirconia blocks is uniform, reducing the processing procedures and making themand making them suitable for mass production.

Multi-layer gradient zirconia blocks

Multi-layer gradient zirconia blocks are relatively expensive, but multi-layer gradient zirconia blocks can excellently simulate the color levels of natural teeth, enhance the aesthetic effect, and are especially suitable for front teeth restoration.

Zirconia discs and trays

Pay attention to the size and shape selection, which which should match the dental milling machine equipment. The mainstream products on the market today are open furniture with a a main diameter of 98 mm.

3. Compatibility and system integration

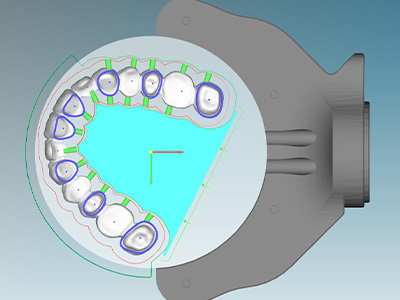

Compatibility with dental systems

Attention all purchasers and bosses, now the mainstream dental zirconia blocks have three specifications: 98 mm, 95 mm, and and 92 * 75 mm, and a rectangular shape, which has slowly withdrawn from the market. Be sure to choose the size and handle design of the zirconia blocks that fit your CAD/CAM equipment o ensure seamless integration andand to avoid problems such as dimensional mismatches in machining.

Software compatibility

Select modules that support mainstream design software to facilitate the interface between digital design and machining processes. Currently, the mainstream CAD/CAM software is Exocad (DentalCAD), 3Shapee Dental System, Millbox, and and hyper DENT.

4. Color and transparency options

High-quality dental zirconia blocks should provide a wide range of color and transparency options to meet the color-matching needs of different patients' mouths, usually 16 Vita colors, BL1, BL2, BL1, BL2, BL3, and4.

Dental multi-layer blocks usually have multiple chromatic levels to enhance the natural feel. Some manufacturers produce dental zirconia blocks with 5 layers of gradient colors, some manufacturers produce dental oxidation with 6 layers, and there are also current manufacturers' claims that they produce zirconia blocks with 8 layers of gradient.

Depending on the location of the restoration and the patient's requirements, it is reasonable to choose a highly transparent or high-strength material. For example, 5Y zirconia blocks are usually used for anterior teeth, and 3Y zirconia blocks r 4Y zirconia blocks are used for posterior teeth.

5. Sintering shrinkage

During the sintering process, the material will shrink to a certain extent.

Choosing a zirconia block with a low and stable shrinkage rate will help improve the dimensional accuracy of the restoration and reduce the time and difficulty of later adjustments.

6. Manufacturing standards and quality control

Give preference to dental zirconia blocks that have passed the FDA r ISO 13485 medical device manufacturing standards.

Traceability: You can check whether the manufacturer's dental zirconia blocks can be traced back. Generally,, dental zirconia blocks will have a UDIDI code, which can be traced back to the date of production andand production batch, and if the manufacturer has a good quality control process, they can guarantee the consistency of the performance and color from batch to batch.

7. Purchase Suggestions and Supplier Selection

Trial and Feedback: It is recommended to prioritize the purchase of sample orders to test the material performance and processing performance nd confirm the applicability before purchasing in bulk.

Supplier Reputation: Priority should be given to suppliers that have been established for a long time nd those that have a good reputation and provide complete technical support and after-sales service.

Technical support: High-quality suppliers should be able to provide processing advice, technical training,, and problem solutions.

Continuous learning: dental material technology is changing rapidly; keep focus on new zirconia technology and new products to optimize material selection in time.

Summary

Choosing the right zirconia block for the dental laboratory is not only about material selection ut also about the quality of the restoration and the patient experience. By taking into account the material composition, quality standards, processing compatibility,, and supplier service, dental laboratories can improve efficiency, ensure restorative results,, and provide patients with more reliable treatment solutions.

Practical procurement demonstration:

First, clear clinical needs, the main core indicators

Mechanical properties: Flexural strength should be selected according to the restoration site; high-strength zirconia with ≥1200 ≥1200 MPaecommended for posterior restorations (e.g.,, HONCHON's HT PC series), and materials with 850-1000 MPaa and light transmittance (e.g.,, HONCHON's STC series r UT series) are recommended for the anterior esthetic area.

Aesthetic compatibility: Transparency (40%-50%) and colorimetric system need to match the natural tooth color level. It is recommended to choose a brand that is compatible with the mainstream colorimetric plates (e.g., VITA 16-color), such as Changsha Honchon Technology Co.

Processing compatibility: CAD/M system adaptability directly affects the cutting efficiency. The The Honchon open model an be compatible with mainstream 98mm furniture. Each dental zirconia block side of the sticker shrinkage an be directly viewed o as to reduce the sintering shrinkage error.

Second, brand technology generation comparison

Fourth-generation zirconia (such as ultra-transparent multilayer): gradient translucent design, suitable for anterior veneers and single crowns, but the strength is slightly lower than the traditional 3Y-TZP..

3rd generation high translucency materials: balanced strength (1000-1200 MPaa) and transparency, suitable for bridges with spans ≤ 3 units

Economical basic models, such as our prefabricated coloring series, are are moderately priced, fully functional, and and suitable for dental laboratories with limited budget purchases.

Third, the laboratory practical advice

Quality control verification: require suppliers to provide fracture toughness (e.g., dental zirconia blocks used as anterior teeth, such as the UT series of fracture toughness ≥ 5 MPa-m¹/², and the rest of the dental zirconia blocks fracture toughness ≥ 8 MPa-m¹/²) and density (≥ 6 6 g/cm³) of the test report.

After-sales system: Prefer brands that offer a 5-year warranty (e.g., HONCHON) and can complete the traceability service.

Sample testing: small batch trial processing to evaluate sintering shrinkage (<15% recommended) and dyeing stability.

Ready to upgrade your dental lab with high-quality zirconia blocks? Contact us today to find the right solution for your needs.