Mastering Pre-shaded Zirconia Blocks: From Material Selection to Aesthetic Excellence

2025-07-09

By Amanda Wu – R&D Engineer at Honchon

Introduction: Why Pre-Shaded Zirconia Is a Game-Changer

As dentists and technicians demand more natural-looking restorations without compromising strength, pre-shaded dental zirconia blocks have rapidly become a preferred material in CAD/CAM dentistry. These blocks integrate mechanical performance (up to 1200 MPa) with built-in chromatic gradients, eliminating the need for manual staining and reducing processing time.

At Honchon, we’ve dedicated years to developing multilayer zirconia systems that combine technical accuracy with clinical beauty—especially in anterior and full-contour applications.

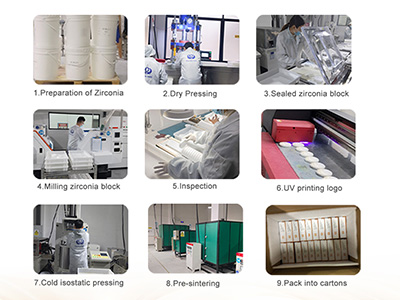

1. Material Science: The Foundation of Quality

The effectiveness of a pre-shaded zirconia block starts at the molecular level.

We source our powders from TOSOH (Japan) and Guoci (China), ensuring:

Consistent particle size distribution

Stable yttria content (3Y-TZP to 5Y-PSZ)

Minimal shrinkage variation during sintering

Through hydrothermal synthesis, we produce nano-zirconia powders that support:

Color stability across VITA 16 shades + bleach options

Translucency gradient: 49% (incisal) → 42% (cervical)

Strength gradient: 800–1200 MPa multilayer structure

These optimized powders form the base of our STP and SHTP series blocks, designed for anterior esthetics and long-span bridges alike.

2. Multilayer Design: Replicating Natural Teeth

Modern pre-shaded blocks use 5–9 gradient layers, and our latest 4D systems offer 15 subtle transitions, creating lifelike effects such as:

Incisal halo

Mid-coronal chroma saturation

Cervical opalescence

Unlike hand-colored or mono blocks, these multi-layered structures ensure color harmony throughout the restoration—even after milling and sintering.

Our STP Color Blocks are precisely layered to simulate the optical behavior of enamel and dentin, making them ideal for aesthetic zones.

3. Clinical Advantages: More Than Just Looks

Workflow Efficiency

Eliminates chairside staining

Saves up to 30% sintering time

Compatible with most open CAM systems

Bioesthetic Performance

High translucency and color depth

Better light diffusion for anterior restorations

Reduced remakes due to improved color consistency

Material Safety

All Honchon zirconia blocks are certified for:

ISO 13485 and CE / FDA compliance

Aging resistance to avoid low-temperature degradation

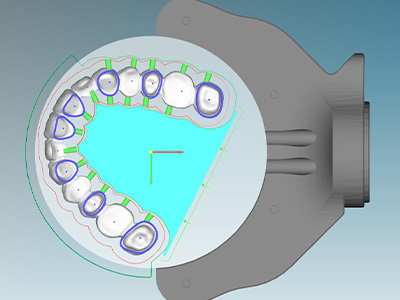

4. Milling & Processing: What Labs Should Know

To ensure optimal outcomes:

Follow manufacturer’s sintering curves

Use compatible milling systems (open 98mm, AG 95mm, etc.)

Maintain CAM parameters for clean edge detailing

Our blocks are compatible with Roland, Amann Girrbach, and other open systems, with shrinkage ratios precisely calibrated.

5. Looking Ahead: The Future of Pre-Shaded Zirconia

Pre-shaded zirconia technology is evolving fast. Future innovations include:

AI-based shade matching software

3D-printed zirconia gradients

Smart materials with adaptive thermal expansion

At Honchon, we are actively developing next-gen zirconia blocks tailored to regional shade preferences and functional demands, with a current clinical acceptance rate of 98.7% in anterior restorations.

Conclusion: Not Just a Material – A Strategy

Choosing the right pre-shaded zirconia block isn’t just about strength or shade—it’s about restoring confidence in every smile. From raw material to multi-layer design, Honchon’s approach reflects our commitment to scientific precision and clinical success.

If you're looking for zirconia blocks that deliver both beauty and performance, our team is here to support you with technical advice, samples, and OEM/ODM solutions.

Contact us today to learn more or request a quote.

Contact us

Email luis@honchon.com

WhatsApp: 8613055185196