Zirconia block manufacturing process in-depth analysis

2025-05-27

I. Core manufacturing process

Raw material preparation

Stabilizer doping: Add 3 mol% Y₂O₃ (yttrium oxide) as tetragonal phase stabilizer to inhibit the volume expansion caused by monoclinic phase transition.

Nanopowder synthesis: Synthesize ZrO₂ powder with particle size ≤50nm by co-precipitation method or hydrothermal method to ensure grain uniformity.

Powder treatment and molding

Spray granulation: Add PVA (polyvinyl alcohol) binder and form microspheres with excellent fluidity (particle size 80-150μm) by centrifugal atomization.

Dry compression molding: press the blanks under pressure ≥200MPa, and control the density deviation within ±0.1g/cm³.

Cold Isostatic Pressing Strengthening: Eliminate interlayer density difference by uniform pressure application at 200-300MPa (key process).

Pre-sintering and precision processing

Pre-sintering parameters: 900-1100°C low temperature pre-sintering to form a porous structure (density of about 50%), which is easy to cut and mold.

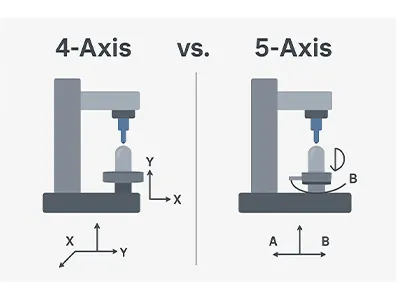

CAD/CAM machining:

Cutting accuracy ≤25μm (5-axis machine)

Compensation of sintering shrinkage 20-25% after cutting (patented algorithm by Wieland)

High temperature sintering and strengthening

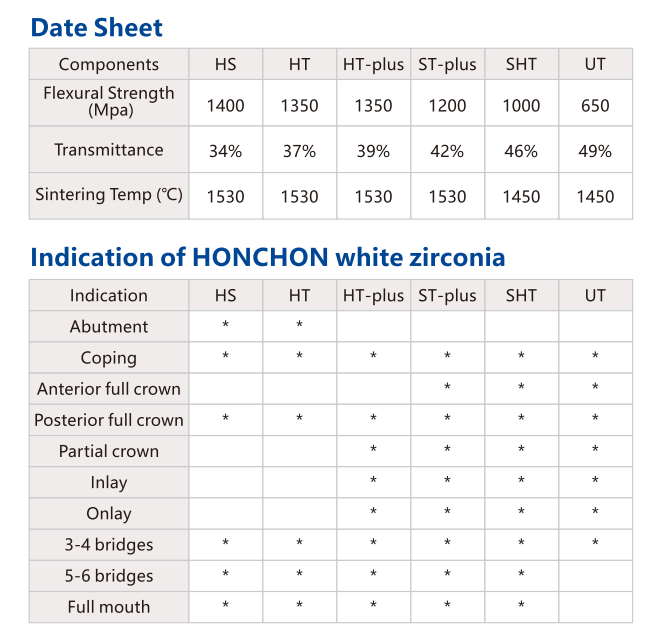

Peak sintering temperature: 1350-1550°C (adjusted according to brand process differences), holding time 2-4 hours to achieve densification.

HIP post-treatment:

Hot Isostatic Pressure (HIP) at 1300°C/100MPa under argon environment, porosity reduced to <0.02%

Surface treatment and aesthetic optimization

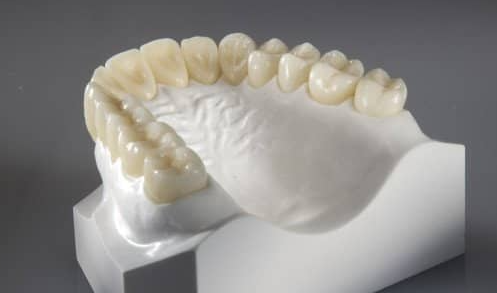

Nanoscale polishing: use diamond grinding paste (particle size 0.1-0.5μm) to polish to Ra ≤ 0.05μm.

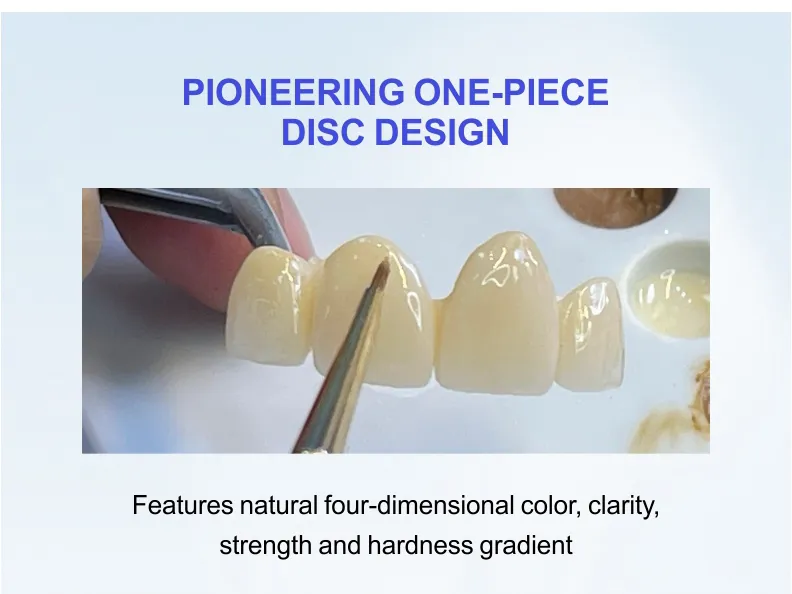

Gradient Dyeing Technology: Penetrating dyeing solution to achieve A1-A3 transparency gradient (Eltron Multi-layer Stacking Technology).

Comparison of key process parameters

Process link Imported brand parameters (Weiland) Domestic brand parameters (Aerotron)

Powder particle size ≤30nm (SEM detection) ≤50nm (laser particle size meter detection)

Sintering temperature 1450℃±10℃ (gradient sintering) 1380℃±20℃ (conventional sintering)

Flexural strength Flexural strength ≥1400MPa (ISO 6872 certification) ≥1200MPa (national standard YY0716 requirements)

Third, the process difficulties and solutions

Crack control:

pre-sintering stage using stepped temperature (100 ℃ / h → 50 ℃ / h) to reduce the thermal stress

Cutting path optimization to avoid stress concentration (Zekang five-axis path compensation algorithm) (Zeccon 5-axis path compensation algorithm)

Color stability:

Sintering atmosphere control (oxygen partial pressure ≤10-⁶Pa) to prevent Y₂O³ decomposition and discoloration

Precise control of dye penetration depth (error ±0.1mm)

Emerging process breakthroughs

Microwave sintering:

Sintering time reduced by 50% (Wieland lab data)

Grain size uniformity increased by 30% (SEM observation)

Additive Manufacturing:

Light-curing 3D printing of zirconia paste, layer thickness accuracy of 20μm (Densburg Sirona pilot phase)

Note: Differences in process parameters directly affect the transmittance (A1-A3 grading) and mechanical properties of zirconia blocks, clinical selection should be combined with branded real-world data (e.g., VITA Easyshade testing).