Premium Dental Zirconia Blocks – Strong, Aesthetic CAD/CAM Restorations

2025-11-19

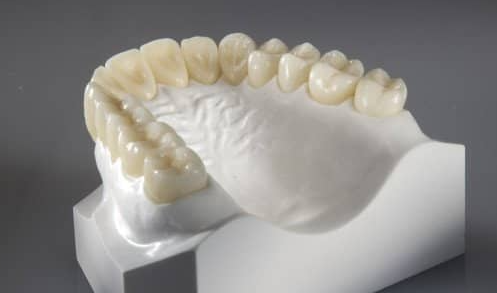

Dental zirconia blocks are high-performance ceramic materials used for a wide range of CAD/CAM restorations. They are primarily composed of stabilized zirconium oxide, known for its excellent strength, durability, and biocompatibility. Zirconia’s molecular structure closely resembles the characteristics required for natural tooth restorations, making it suitable for fabricating crowns, bridges, veneers, inlays/onlays, and implant-supported prostheses.

Due to their stability, resistance to high temperatures, chemical inertness, and the ability to mimic natural tooth color, zirconia blocks have become one of the most reliable restorative materials in modern dentistry.

Applications of Dental Zirconia Blocks

Dental zirconia blocks can be used for various restorative treatments, including:

1. Crowns and Bridges

Ideal for repairing chipped, discolored, or missing teeth. Zirconia offers excellent strength and aesthetics, ensuring durability and natural appearance.

2. Veneers

Used to improve tooth surface smoothness, color, and alignment. Zirconia veneers help enhance the smile with long-lasting stability.

3. Inlays and Onlays

Suitable for cases where tooth structure is severely damaged. Zirconia inlays/onlays restore chewing function and maintain the natural shape of the tooth.

4. Implant Restorations

Zirconia can be used as implant abutments or crowns to restore missing teeth with excellent tissue compatibility and mechanical stability.

Advantages of Dental Zirconia Blocks

Zirconia is widely chosen by dental professionals due to the following benefits:

High strength and fracture resistance

Excellent wear and abrasion resistance

Stable chemical properties

Low thermal conductivity

High toughness and elasticity modulus

Biocompatibility and low allergenicity

Natural and aesthetic appearance

Although zirconia blocks are more expensive and require advanced production and processing, the clinical results and longevity they provide make them a preferred option.

How Dental Zirconia Blocks Are Made (Principle)

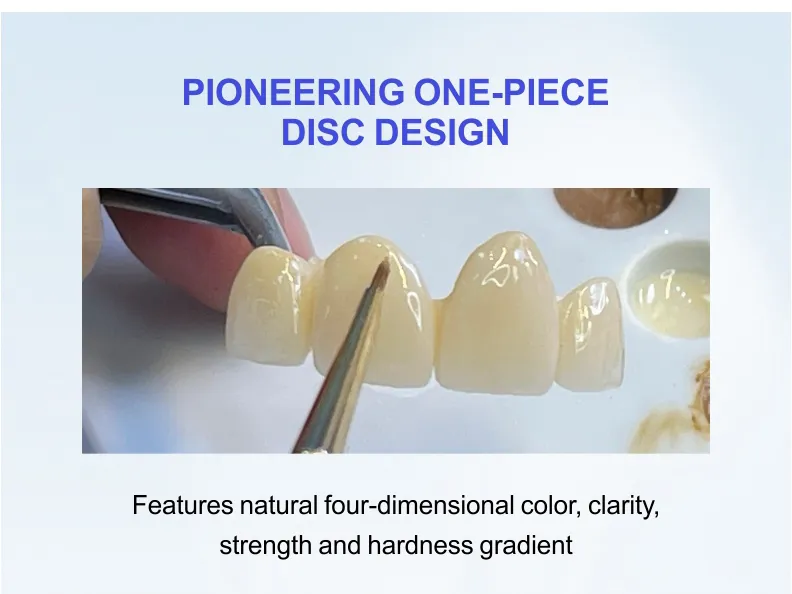

Dental zirconia blocks are manufactured through a high-precision process. High-purity zirconia powder is pressed, shaped, and then pre-sintered in a high-temperature furnace. This process creates a stable internal structure and provides the necessary mechanical properties for milling and final sintering.

Key features of zirconia material performance include:

High hardness and strength at high temperatures

Resistance to chemical corrosion

Excellent biocompatibility without irritation

Ability to maintain stable structure after milling and sintering

Because zirconia achieves a balance between function and aesthetics, it has become a mainstream material used by dental labs and clinics globally.

How Dental Zirconia Blocks Are Used Clinically

The clinical workflow of zirconia restorations typically includes:

Oral cleaning and preparation

The tooth and surrounding tissues are cleaned and disinfected.

Tooth preparation

The dentist shapes the tooth for restoration and takes a digital scan.

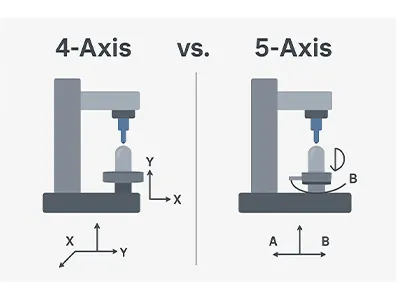

CAD/CAM design and milling

The zirconia block is milled based on the digital design.

Sintering

The milled zirconia restoration is sintered in a furnace to achieve final strength.

Adjustment and polishing

The restoration is adjusted to ensure proper fit and occlusion.

Cementation

A specialized adhesive is used to bond the zirconia restoration securely to the tooth.

This process ensures accuracy, strength, and long-term stability.

Precautions When Handling Dental Zirconia Blocks

To ensure optimal performance and safe usage, consider the following:

Avoid strong impacts

Zirconia is strong but surface micro-cracks may occur under sudden impact.

Avoid contact with acidic or fluoride-rich chemicals

These may cause surface corrosion.

Control sintering temperature

Excessive preheating or rapid temperature changes may cause cracking.

Use proper protective equipment

Gloves and protective glasses help avoid injury during milling or handling.

Store properly

Keep zirconia blocks in a dry, ventilated environment away from direct sunlight.

Follow dental procedures strictly

Proper technique ensures both safety and restoration quality.