Dental Lithium Disilicate Glass Ceramics — Properties, Manufacturing Process, and Clinical Applications

2025-11-19

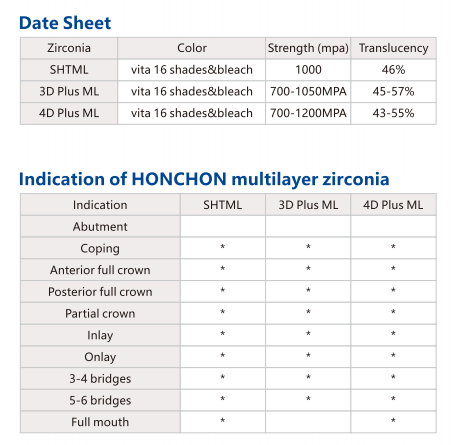

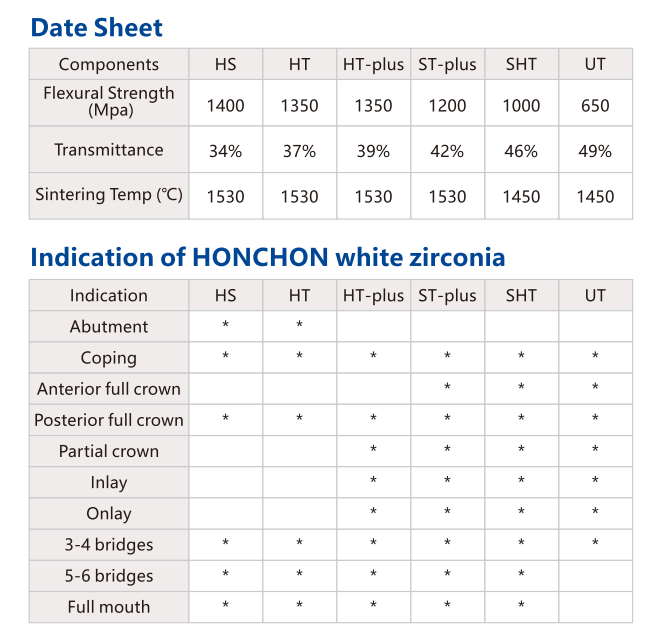

Dental lithium disilicate glass ceramics—often simply called lithium disilicate ceramics—have become one of the most widely used restorative materials in modern dentistry. In China, major manufacturers such as Aidite, Upcera, and HONCHON Smile are actively producing lithium disilicate blocks and ingots for CAD/CAM and pressing systems.

This material is favored for its high strength, excellent translucency, and impressive esthetic performance, making it suitable for a wide range of restorative indications.

Below is a complete, easy-to-understand analysis of its key characteristics, preparation process, and clinical uses.

1. Characteristics of Lithium Disilicate Glass Ceramics

1. High Mechanical Strength

Lithium disilicate ceramics typically feature:

Flexural strength: around 400 MPa

Excellent fracture toughness

High resistance to chewing forces

These properties ensure long-term stability and reliability, even in high-load areas of the oral cavity.

2. Excellent Biocompatibility

As a non-toxic, non-irritating ceramic material, lithium disilicate exhibits outstanding biological safety.

It does not trigger allergic reactions and is highly compatible with oral soft and hard tissues, making it suitable for long-term wear in the mouth.

3. Superior Esthetic Properties

Lithium disilicate stands out for its impressive esthetics:

Tooth-like translucency

Natural optical behavior

Wide shade selection

These qualities allow clinicians and dental technicians to achieve restorations that closely mimic natural enamel and dentin, delivering highly esthetic outcomes.

2. Preparation Process of Lithium Disilicate Glass Ceramics

Although the full manufacturing process is complex, the core production workflow can be summarized in three key steps:

1. Batching and Melting

Raw materials—mainly silica, lithium oxide, and other oxides—are mixed in precise ratios and melted at high temperatures to form a uniform glass melt.

This step directly affects the purity and stability of the final ceramic.

2. Molding and Heat Treatment

The molten glass is cast into molds to create the desired shapes (such as blocks or ingots).

Subsequent heat treatment allows controlled crystallization, significantly enhancing:

Flexural strength

Thermal stability

Fracture resistance

This is the critical step that forms the lithium disilicate microstructure.

3. Processing and Polishing

Finally, the shaped ceramics undergo precision milling, fine grinding, and polishing to achieve:

Accurate marginal fit

Smooth surface quality

Optimal translucency

The finished product can then be used in CAD/CAM systems or for traditional hot-pressing workflows.

3. Applications of Lithium Disilicate Ceramics in Dentistry

Lithium disilicate’s mechanical strength, translucency, and biocompatibility make it suitable for a wide range of restorative treatments.

1. Dental Veneers

Lithium disilicate veneers can dramatically improve:

Tooth color

Minor misalignment

Shape irregularities

They are particularly useful for treating:

Yellow or discolored teeth

Tetracycline staining

Enamel defects

The esthetic effect is highly natural, making it a top choice for smile design.

2. Crowns and Bridges

Thanks to its flexural strength and fracture toughness, lithium disilicate is used for:

Full-coverage crowns

Short-span bridges (typically anterior or premolar regions)

Its thermal properties and translucency allow restorations that are both functional and beautifully lifelike.

3. Implant Restorations

Lithium disilicate can also serve as:

Implant crowns

Custom abutments (in some systems)

Its ability to integrate visually with surrounding teeth and tissues enhances the esthetic outcome of implant restorations.

Conclusion

With its excellent mechanical properties, esthetic performance, biocompatibility, and aging resistance, lithium disilicate glass ceramic has become a core material in modern restorative dentistry. As technology continues to advance, the quality and versatility of lithium disilicate will only improve, bringing patients more natural, durable, and functional restoration solutions.