4-Axis vs. 5-Axis Dental Milling Machines — How to Choose the Right One for Your Lab

2025-11-19

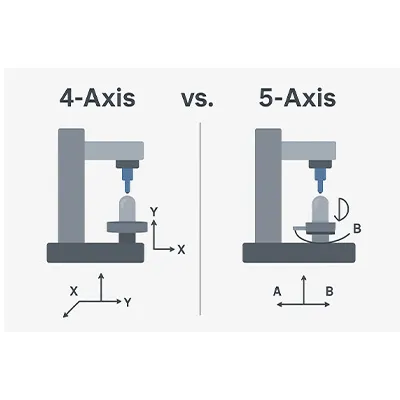

Choosing between a 4-axis and a 5-axis milling machine is one of the most common—and often most confusing—decisions for dental labs. Many technicians worry that a 4-axis machine may limit machining capabilities, while others believe a 5-axis unit is always the superior option.

In fact, the best choice depends heavily on your lab’s daily workload, restoration types, and future expansion plans.

Below is a clear and practical comparison to help you decide which system truly fits your needs.

1. 4-Axis Dental Milling Machine

Number of Motion Axes

A 4-axis system includes three linear axes (X, Y, Z) and one rotary axis (usually the A-axis).

This combination is sufficient for most conventional milling tasks.

Machining Range

A 4-axis machine can complete most 3D restorations, but the single rotary axis limits multi-angle machining.

For standard indications such as:

Crowns

Inlays/onlays

Simple bridges

a 4-axis unit provides more than enough capability.

Machining Efficiency

Because of the limited rotation, some cases require reclamping. Each extra clamping step may increase preparation time and introduce potential inaccuracies.

For routine restorations, however, the speed and precision are fully adequate.

Ideal Applications

A 4-axis milling machine is an excellent option for labs that focus on:

daily crown and bridge work

temporary restorations

predictable, standardized cases

It offers a good balance between cost and performance.

2. 5-Axis Dental Milling Machine

Number of Motion Axes

A 5-axis system includes X, Y, Z and two rotary axes (A & B).

This dual-rotation structure allows the machine to mill complex angles and undercuts that are impossible for a 4-axis unit.

Machining Range

With more freedom of movement, a 5-axis machine can mill multiple surfaces from different angles in a single clamping.

This greatly improves accuracy and enables the fabrication of:

customized implant abutments

implant bridges

deep undercut areas

highly individualized all-ceramic crowns

Machining Efficiency

Since most jobs can be completed in one clamping, the 5-axis system not only shortens production cycles but also improves precision. It is especially efficient when handling complex or highly detailed designs.

Ideal Applications

A 5-axis milling machine is the preferred option for labs dealing with:

implant restorations

advanced esthetic cases

multi-unit bridges with angulation

restorations requiring fine detailing

3. Key Factors to Consider

Machining Flexibility

5-axis machines clearly offer superior flexibility, especially when handling complex geometries.

However, for labs whose cases are 80–90% routine crowns and bridges, the additional flexibility may not translate into significant daily advantages.

Cost vs. Real Needs

A 5-axis system is more expensive and requires more advanced operator knowledge.

A 4-axis system is more cost-effective and easier to operate, making it a solid choice for labs with limited budgets or standardized workflows.

Current vs. Future Workload

Choose based on your lab’s real needs:

Primarily simple restorations?

→ A 4-axis machine is enough and offers great value.

Planning to accept more implant work or customized restorations?

→ A 5-axis machine will better support long-term growth.

4. Common Misunderstandings (Important!)

Many labs struggle with these misconceptions:

Misunderstanding 1: “4-axis machines can’t produce quality restorations.”

In reality, a good 4-axis unit easily handles most daily crown and bridge work.

Misunderstanding 2: “5-axis is always better.”

Not if most of your orders are standardized cases. Many labs invest in 5-axis machines but only use 30–40% of their capabilities.

Misunderstanding 3: “5-axis machines always provide higher precision.”

Precision depends more on mechanical stability, software, and tooling—not the number of axes alone.

5. Practical Selection Advice

To help you make a quick and realistic decision:

Budget is limited → Choose 4-axis

Mostly crowns/bridges → Choose 4-axis

Only one machine in the lab → Choose 5-axis

High volume implant work → Choose 5-axis

Planning to scale up services → Consider 5-axis

A common and very effective setup is:

4-axis for daily standard restorations

5-axis for complex or implant cases

This combination gives both efficiency and flexibility.

6. Conclusion

Both 4-axis and 5-axis milling machines play essential roles in modern dental laboratories:

4-Axis Milling Machine

Ideal for everyday restorations—simple to use, cost-effective, and highly reliable for routine tasks.

5-Axis Milling Machine

Designed for complex, highly detailed, or implant-related jobs. While more costly, it brings greater freedom, precision, and efficiency.

The right choice depends on your lab’s case mix, budget, and long-term development plans. Selecting equipment that matches your actual needs will ensure stable performance and sustainable growth.