Dental Milling Burs Manufacturer – Honchon Smile Official Guide

2025-05-23

Premium Milling Tools for Dental Labs, Clinics, and CAD/CAM Centers

OEM & ODM Orders Welcome | Long-Lasting Performance | Factory Direct

1. What Are Dental Milling Burs?

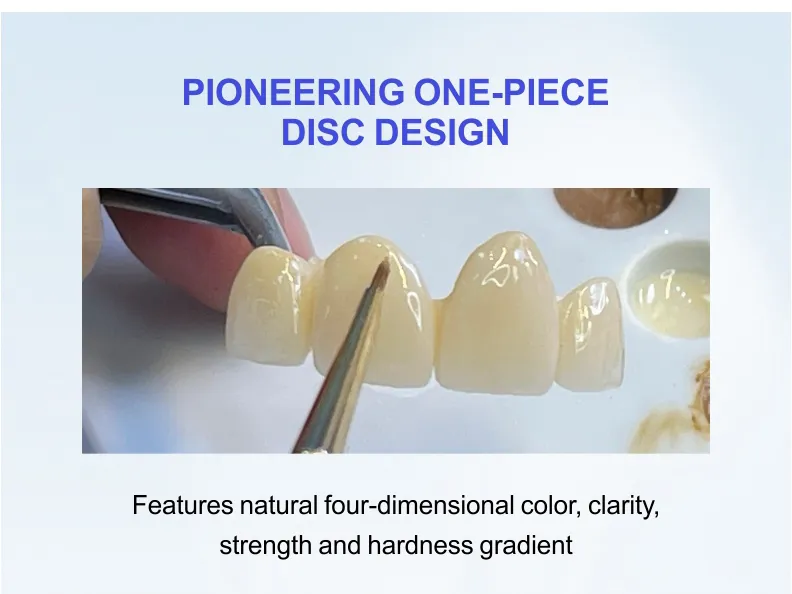

Dental milling burs are precision cutting tools used in CAD/CAM milling machines to carve dental restorations from materials like zirconia, PMMA, wax, and glass ceramics. These burs come in different diameters and shapes for roughing, finishing, and detailing. The quality of the bur directly affects milling accuracy, surface finish, and crown longevity.

At Honchon Smile, we provide high-quality burs engineered for maximum performance and compatibility with leading systems such as Roland, VHF, Amann Girrbach, Sirona, and more.

2. Advantages of Honchon Smile Dental Milling Burs

Longer Lifespan – Up to 80 crowns per bur (zirconia)

High Precision – Clean margins, minimal chipping

Stable Performance – Smooth cutting, less vibration

Material-Specific Geometry – Designed for zirconia, PMMA, wax, etc.

Wide Compatibility – Covers Roland, VHF, imes-icore, AG, etc.

OEM Support – Custom logo, label, packaging, specs

3. Material & Coating of Dental Milling Burs

Our burs are made from ultra-fine grain tungsten carbide, finished with:

DLC Coating – For zirconia (high hardness, low friction)

Diamond Coating – For glass ceramics and long-life zirconia cutting

Uncoated or Teflon Burs – For PMMA, wax, soft resin

Each coating is optimized for specific materials to improve efficiency and reduce heat buildup.

4. Applications of Dental Milling Burs

Honchon Smile burs are widely used for milling:

| Material | Recommended Coating | Common Use |

|---|---|---|

| Zirconia | DLC / Diamond | Crowns, Bridges, Inlays |

| PMMA | Uncoated / Teflon | Temporary crowns, Models |

| Wax | Uncoated | Full-contour design milling |

| Glass Ceramics | Fine-grain Diamond | Esthetic anterior restorations |

5. Tool Life & Milling Performance

Zirconia milling: 60–80 units per bur

PMMA/Wax milling: 100+ units per bur

No overheating or cracking when used with proper cooling

Passed real-lab testing with Roland DWX, VHF K5, and AG systems

Client testimonials available upon request

6. Manufacturing Process

Raw Material Selection (Tungsten Carbide Rods)

Precision CNC Grinding

Micro Coating Application

High-Speed Balance Testing

Tool ID Laser Engraving

Final Quality Inspection

Strict QC ensures every bur meets international standards.

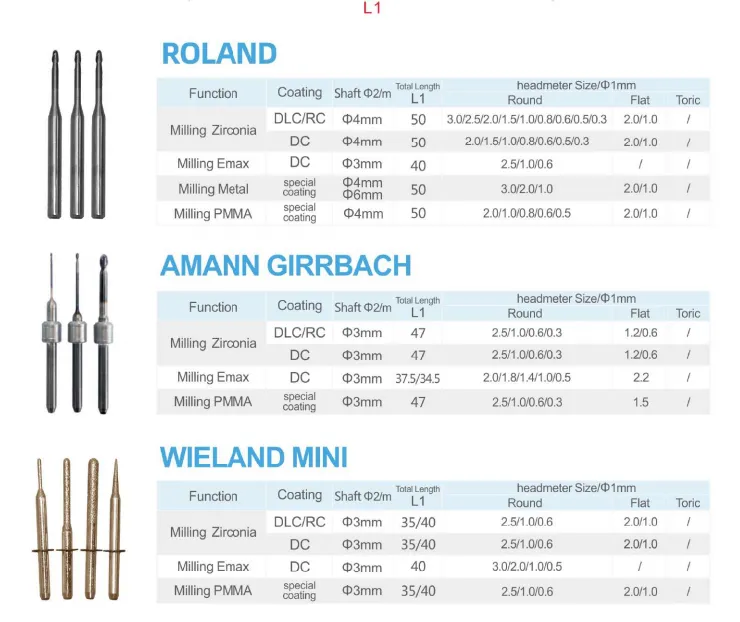

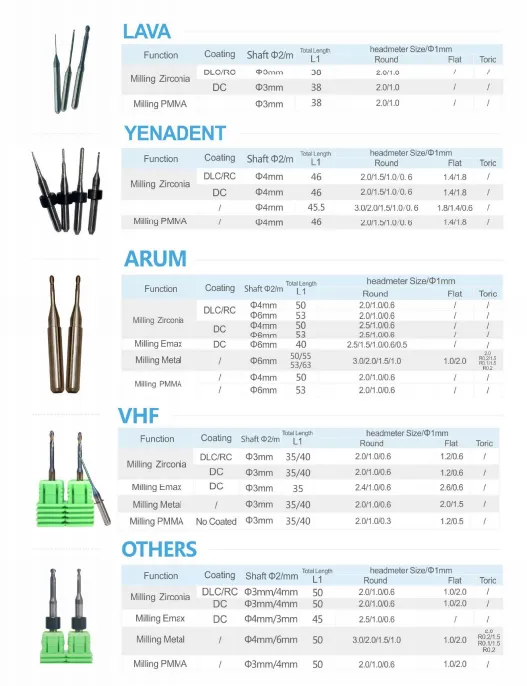

7. Compatibility with Milling Machines

We supply burs for all major dental milling systems:

Roland DWX series

VHF S1/S2/K4/K5/K5+ series

Amann Girrbach (AG)

imes-icore

Sirona InLab

Wieland, Zirkonzahn, and more

Custom sizes and non-standard geometries can be produced on demand.

8. How to Cooperate with Us

We offer flexible cooperation for:

OEM orders (logo, label, box)

Mixed model orders

Custom bur sizes or geometries

Worldwide export & logistics support

Just tell us your machine model, material, and bur size requirements — we will offer the best solution.

9. Certifications & Compliance

ISO 13485 Certified

CE Mark Available

Full traceability and batch tracking

Factory audit reports & MSDS available upon request

10. Our Factory – Honchon Smile

Honchon Smile is located in Changsha, China, and has a clean CNC tool shop equipped with:

Advanced 5-axis grinding equipment

In-house R&D and quality laboratory

14 years of tool manufacturing experience

Annual output: more than 500,000 needles

11. Frequently Asked Questions (FAQ)

1. what is the material and coating style of dental milling burs?

Our milling burs are made of high quality tungsten carbide with optional DLC or diamond coating for superior durability and heat resistance, ensuring precise and long-lasting performance.

2. dental milling burs are compatible with which dental milling machines?

Our regular stock of dental milling burs are compatible with all major systems on the market:

e.g. Roland / DWX / VHF / imes-icore / Sirona / Zirkonzahn / AG, etc. We can also customize the dental milling burs, you can send us pictures or samples for customization.

3. What kind of materials can dental milling burs mill?

We offer dental milling burs in the following materials: zirconia, PMMA / wax, glass-ceramics (e.g. E.max), cobalt-chromium metal, each milling cutter is optimized in terms of geometry and coating to obtain the best results on the specific material.

4. What sizes are available for dental milling burs?

Head diameter: 0.5mm / 1.0mm / 2.0mm / 2.5mm / 3.0mm

Overall length: 35mm, 38mm, 45mm or customized

Tool type: roughing, semi-finishing, finishing, detailing

5. What is the life and performance of dental milling burs?

On average, zirconia milling cutters can machine:

60-80 crowns or bridges, depending on material hardness and machine calibration

PMMA/wax milling cutters can last up to 100+ years

When used correctly, there are very few problems with chipping, breakage or overheating.

Internal tests and customer cases show:

More than 1,000 pieces sold with less than 2% breakage rate

Consistent cutting performance until the last case.

✔ We can provide test reports and customer feedback upon request.

6. dental milling burs pricing and minimum order quantities

Unit prices vary by model and coating (e.g., $10 to $20 per piece).

Bulk orders are priced on a tiered basis

Minimum order: 10 pieces of each model, or can be mixed and matched, OEM.

7. How are dental milling burs packaged and shipped?

Individual turning needles are packaged in individual plastic boxes with foam protection in bulk quantities.

Customized labels/barcodes/brand logos are available.

Delivery time:

In-stock items: ship within 1-3 days.

Custom/OEM orders: 5-10 business days.

Shipment via DHL, FedEx or as per your request.

8. whether dental milling burs accepts OEM/ODM orders.

We offer a full range of customization services:

Private labeling (your logo and model number)

Custom sizes, head geometry or color coded caps

Co-design service for new needles, including samples and testing support.

9. After-sales and technical support

provides usage guidelines for optimal results and extended needle life

Replacement or refund if breakage occurs within reason due to tooling defects

We help customers to troubleshoot:

Machine incompatibility

Accidental wear or needle performance issues

Tool life optimization

✔ Our team of experienced dental technicians is here to support you.

12. Packaging & Shipping

Single bur in plastic protective box

Custom label / barcode / branding available

OEM blister, carton, or sticker options for distributors

Shipping via DHL / FedEx / air / sea

Export experience to 30+ countries

Ready to get a quote or sample?

Contact us now to discuss your milling needs.

Email: luis@honchon.com

WhatsApp :+8613055185196