The Role of Dental Titanium Discs in Modern Implantology

2025-07-07

Introduction

As implant dentistry continues to evolve, the materials used in restorative procedures must meet increasingly high standards for biocompatibility, strength, and precision. Among the most trusted materials, dental titanium discs have earned a solid reputation for their exceptional mechanical properties and compatibility with digital workflows. Whether in custom abutments, implant bars, or frameworks, titanium discs are indispensable in producing reliable, long-lasting prosthetic components. This article explores why titanium discs remain a cornerstone in modern implantology and digital dental labs.

What is a Dental Titanium Disc?

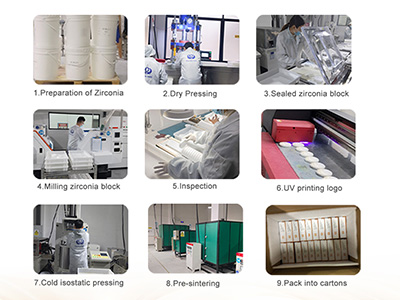

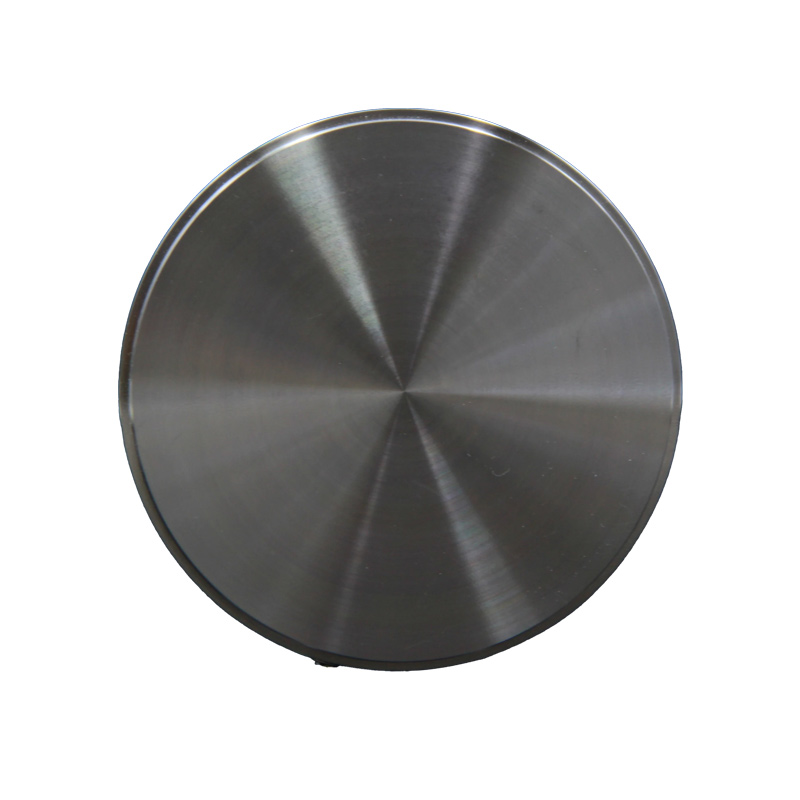

A dental titanium disc is a circular block of medical-grade titanium used with CAD/CAM milling systems to produce a wide range of implant-supported restorations. These discs are available in various grades (typically Grade 2, Grade 4, or Grade 5/Grade 23 - Ti6Al4V ELI) and thicknesses, and are engineered for high-precision milling.

Titanium is known for its biocompatibility, corrosion resistance, and excellent strength-to-weight ratio, making it an ideal choice for dental implants and prosthetics that need to last in the oral environment.

Key Advantages of Dental Titanium Discs

1. Excellent Biocompatibility

Titanium is naturally biocompatible and osseointegrates well with bone, which makes it a perfect material for dental implants and custom abutments. It is well-tolerated by the human body and rarely causes allergic reactions.

2. High Strength and Durability

Titanium offers outstanding tensile strength and fatigue resistance, making it ideal for prosthetic components that must withstand constant chewing forces.

3. Corrosion Resistance

The naturally forming oxide layer on titanium surfaces prevents corrosion, even in the moist, acidic conditions of the oral cavity. This ensures long-term stability.

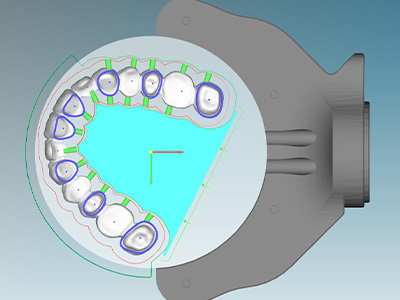

4. CAD/CAM Milling Compatibility

Dental titanium discs are designed for use with CAD/CAM systems, allowing for high-precision, repeatable production of custom implant parts, abutments, bars, and bridges.

5. Versatile Applications

Available in different grades and dimensions, titanium discs can be used for:

Custom abutments

Screw-retained crowns

Full-arch implant bars

Hybrid dentures frameworks

Temporary abutments or healing caps

6. Lightweight and Patient-Friendly

Titanium’s light weight adds to patient comfort—especially important in full-arch restorations and large frameworks.

Common Applications in Dentistry

1. Custom Implant Abutments

Milled from titanium discs, custom abutments allow for optimal emergence profiles, ensuring better soft-tissue adaptation and improved aesthetic outcomes.

2. Implant Bars and Bridges

Titanium discs are used to mill implant bars, which support full-arch prostheses like All-on-4 or hybrid dentures. These structures require both strength and precision.

3. Temporary Components

Lower-grade titanium discs (e.g., Grade 2) can be used for temporary abutments or healing caps during implant healing phases.

4. Hybrid Frameworks

Titanium frameworks provide strong yet lightweight support for composite or ceramic veneering materials in full-arch prosthetics.

Titanium Grades in Dentistry: A Quick Comparison

| Grade | Composition | Use Case | Strength Level | Notes |

|---|---|---|---|---|

| Grade 2 | Commercially pure | Temporary abutments, simple bars | Moderate | Easy to machine, cost-effective |

| Grade 4 | Commercially pure | Implant abutments, long-span bridges | High | Best balance of strength & machinability |

| Grade 5 / 23 | Ti-6Al-4V ELI | Complex bars, load-bearing structures | Very High | Superior mechanical properties |

The Future of Titanium Discs in Digital Dentistry

With digital workflows becoming the standard in prosthetic dentistry, titanium discs continue to evolve alongside advanced milling systems, laser sintering, and 3D printing. The integration of AI-driven design, improved coating technologies, and surface treatment innovations (e.g., anodizing, sandblasting) are making titanium restorations more aesthetic and efficient than ever before.

Conclusion

Dental titanium discs remain an essential material in the modern dental laboratory. Their unmatched strength, biocompatibility, and suitability for digital manufacturing make them ideal for a wide range of restorative applications. As dentistry moves further into the era of digital customization and chairside efficiency, titanium discs will continue to support high-quality, long-lasting patient outcomes.

Whether you’re fabricating a single abutment or a full-arch bar, titanium offers the performance and precision that dental professionals trust.