1.Product Introduction:

Dental cad cam milling burs are produced by Changsha honchon Technology Co., Ltd. These dental cad cam milling burs are compatible with Amann Girrbach's machines. Dental cad cam milling burs can cut four denture materials, namely metal, emax PMMA and zirconia. , the biggest advantages of dental cad cam milling burs are precise cutting and long service life, so they are very popular among customers!

2.Product Parameter:

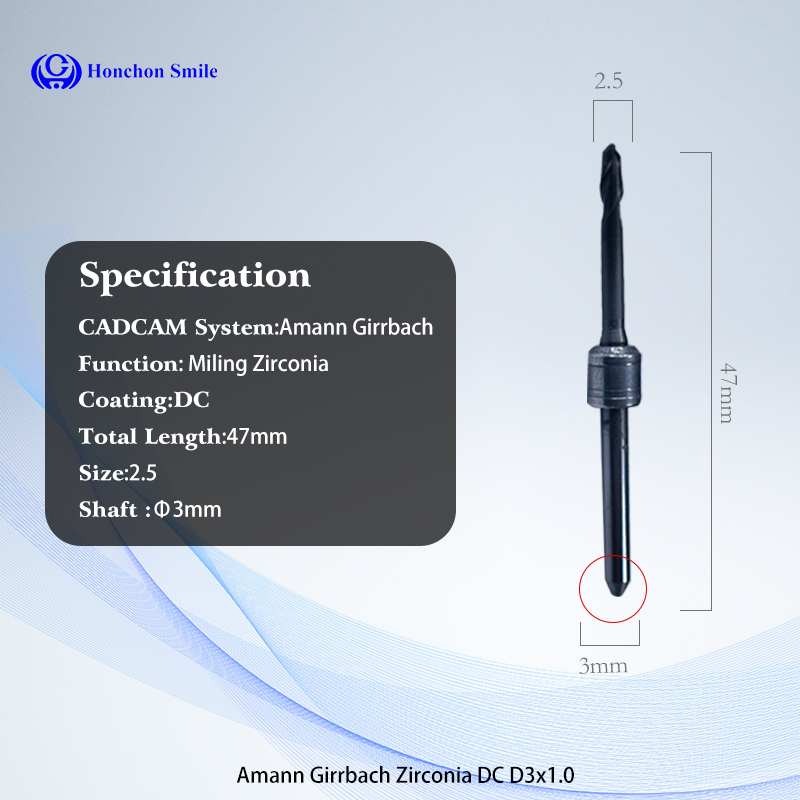

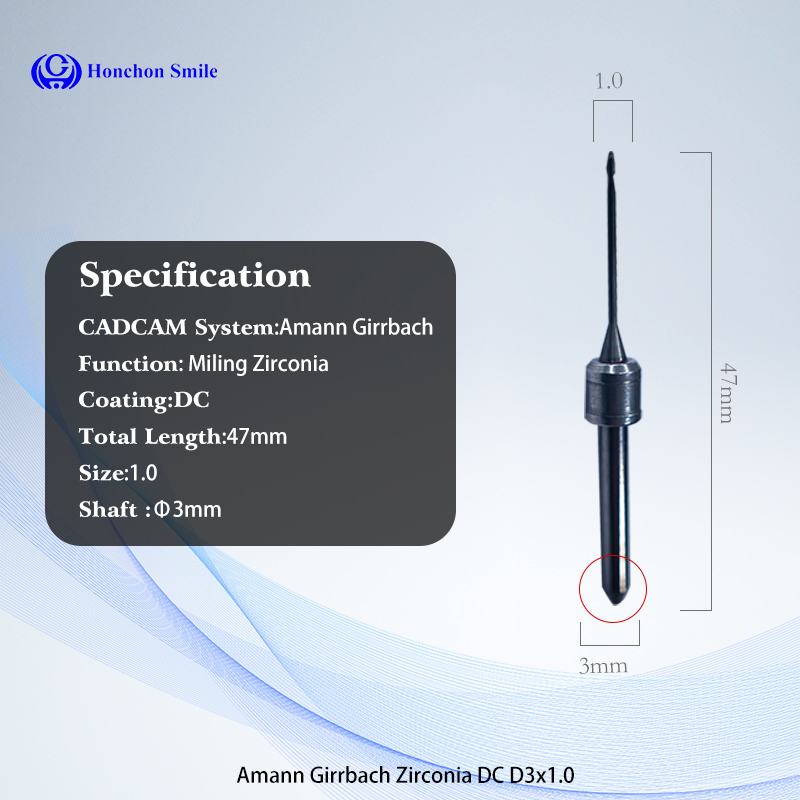

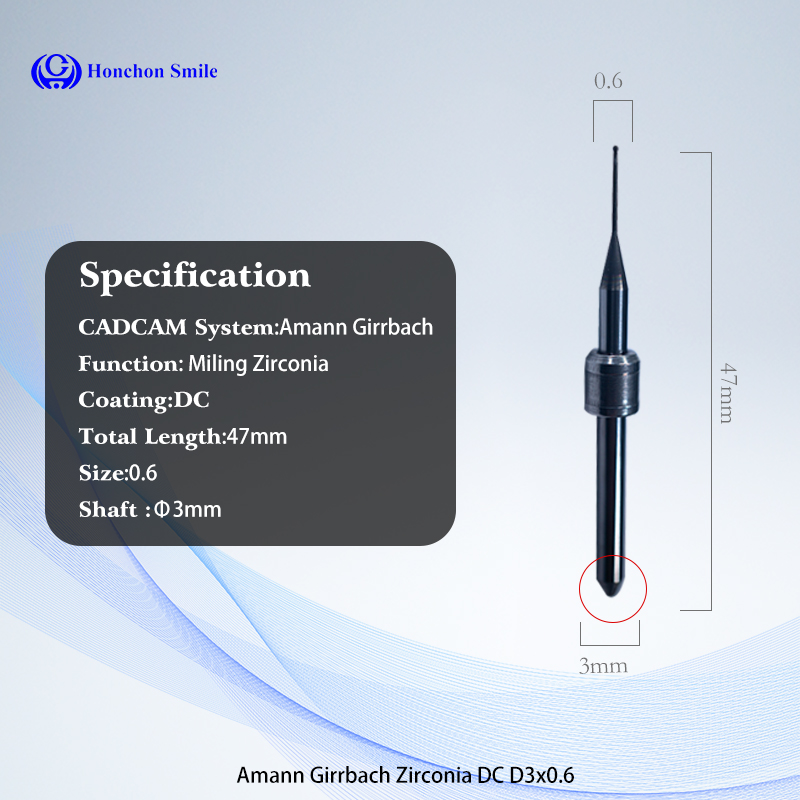

Compatibility: Amann Girrbach machines

Coating: DC/RC/DLC coating

Size: 0.3/0.6/0.7/1.0/2.0/2.5

Material: High purity tungsten carbide

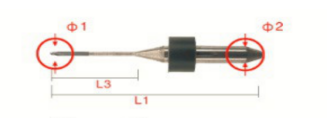

| |||||||

| CADCAM System | Function | Coating | Shaft Φ2/mm | Total Length L1/mm | headmeter Size/Φ1mm | ||

| Round | Flat | Toric | |||||

| Amann Girrbach | Milling Zirconia | DLC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | 1.2/0.6 | / |

| RC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | / | / | ||

| DC | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | / | / | ||

| Milling Emax | DC | Φ3mm | 44 | 1.8/1.4/1.0/0.4 | 2.2 | / | |

| Miling Metal | / | / | / | 2.0/1.0 | / | / | |

| Miling PMMA | / | Φ3mm | 47 | 2.5/1.0/0.6/0.3/2.0 | 1.2/0.6 | / | |

3.Product Features and Application:

Dental cad cam milling burs are used in dental clinics. Dental cad cam milling burs are installed on Amann Girrbach machines and are used for cutting various denture materials. Common denture materials include PMMA/PEEK, zirconia and other denture materials. The product quality of Dental cad cam milling burs is directly related to the quality of the cutting process. bad, so these materials must be chosen carefully.

4.Production Details:

The production of Dental cad cam milling burs includes these processes. The first is computer-aided design. After the design is completed, the materials will be selected according to the design requirements. After the materials are selected, they will be cut. After the cutting is completed, they will be polished. After polishing, they will be tested. The test results After passing, it will be packaged and shipped. Of course, the coated Dental cad cam milling burs will be spray-coated after cutting, which will make the Dental cad cam milling burs have better durability.

5.FAQ:

1. What are the advantages of your dental cad cam milling burs?

1. The product is of high quality and accurately compatible with machines. 2. High cutting precision, short cutting time, 3. Product durability is very good. And we are a factory with more than 10 years of production experience. Our factory has passed ISO/CE certification, and our product quality and production process standards are constantly improving, which makes people favored.

2. What to do if there are quality problems with the products you buy back?

If it is a product quality problem, we can guarantee a return or exchange, and we can provide one-on-one guidance throughout the entire process!

3. The size of Dental cad cam milling burs is very small, will it be damaged during transportation?

Each of our Dental cad cam milling burs is packaged individually. For small-sized Dental cad cam milling burs, we will put a sponge pad on it to prevent damage.

4. Can we come to the factory for on-site inspection?

Yes, our factory receives many customers from all over the world every year. After visiting the factory, they are very satisfied with the quality of our products.

.jpg)