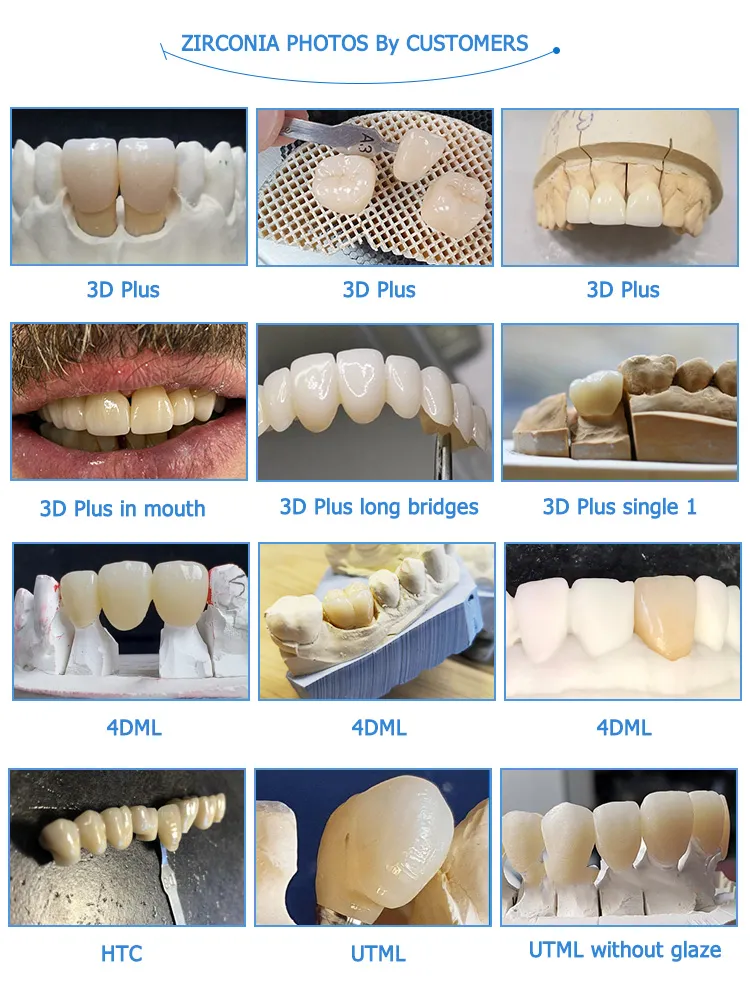

Product Overview

HONCHON SMILE offers high-strength dental zirconia discs suitable for crowns, bridges, veneers, inlays, and implant abutments. Made with yttrium-stabilized zirconia using dry-pressing and cold isostatic pressing, our discs ensure durability, biocompatibility, and excellent aesthetics.

Brand Name: HONCHON SMILE

Country of Origin: Changsha, China

Model Numbers: OD98 / OD95 / AG 92*75

Thickness Options: 10 / 12 / 14 / 16 / 18 / 20 / 22 / 25 mm

OEM/ODM Service: Available

Key Advantages of HONCHON Discs

| Advantage | Description |

|---|---|

| Stable Quality | 16+ years ceramic experience; ISO 13485 & FDA certified |

| Full Range | 8 series: HT, ST-C, ST-ML, SHT-C, ML, Pro-ML, UT-C, UT-ML |

| OEM / ODM | Custom sizes, shades, and packaging for labs and distributors |

| Fast Lead Time | 100k discs/month capacity; 1–3 days for stock items |

| Global Support | English-speaking technical team; real-time WhatsApp support |

Physical & Chemical Properties

Composition: ≥99% ZrO₂ + Y₂O₃ + HfO₂ + Al₂O₃

Flexural Strength: HT/ST/ML >800 MPa; UT >500 MPa

Fracture Toughness: HT/ST/ML >5 MPa·m¹/²; UT >3.5 MPa·m¹/²

Chemical Solubility: <100 μg/cm²

Shrinkage Factor: 1.220–1.260 ±0.002

Linear Thermal Expansion: 10.4 ± 0.5 × 10⁻⁶ K⁻¹

Radioactivity: ≤1.0 Bq·g⁻¹ U238

Note: Pigments for color are evenly dispersed for uniform shades in full-contour restorations.

Available Series & Indications

| Series | Indications | Translucency | Shades |

|---|---|---|---|

| HT | Posterior crowns, long-span bridges | 40 % | White / Pre-shaded |

| ST-C / ST-ML | Full contour crowns & bridges | 43 % | VITA 16 |

| SHT-C / ML / Pro-ML | Esthetic anterior restorations | 47–57 % | A-D + Bleach |

| UT-C / UT-ML | Ultra-esthetic veneers & inlays | 49 % | VITA 16 |

Applications

Crowns, bridges, veneers, inlays, high inlays

Implant abutments

Suitable for anterior and posterior restorations

Different translucency & strength options allow precise clinical selection

Pricing & Ordering

Price Range: USD 20–120 (depending on model, thickness, and quantity)

Mixed thicknesses are accepted with the same shade

Free quotes available upon request

FAQ

Q1: Can I mix thicknesses in one order?

A: Yes, mixed thicknesses are accepted if shades match.

Q2: Do you provide sintering curves?

A: Each box includes a QR code linking to the recommended sintering curve.

Q3: What’s the warranty?

A: Five-year quality warranty. Any confirmed material defect will be replaced free of charge.

Why Choose HONCHON SMILE?

With advanced equipment, strict quality control, and professional support, HONCHON is a trusted partner for dental laboratories, clinics, and distributors worldwide. Our zirconia discs combine strength, aesthetics, and reliability for successful restorations every time.

Contact us today for your customized dental zirconia discs!

.jpg)