1. What is a CAD/CAM zirconia block?

CAD/CAM Zirconia Block is a high-strength, all-porcelain material for restorative dentistry, suitable for dental restorations processed by computer-aided design (CAD) and computer-aided manufacturing (CAM) techniques. The zirconia blocks are used for a wide range of restorative dental applications due to their excellent strength and aesthetic properties. They provide high-precision restorations, especially when used with equipment such as CEREC, inLab, Open Systems, Wieland/Zirkonzahn/Amann Girrbach, and many others.

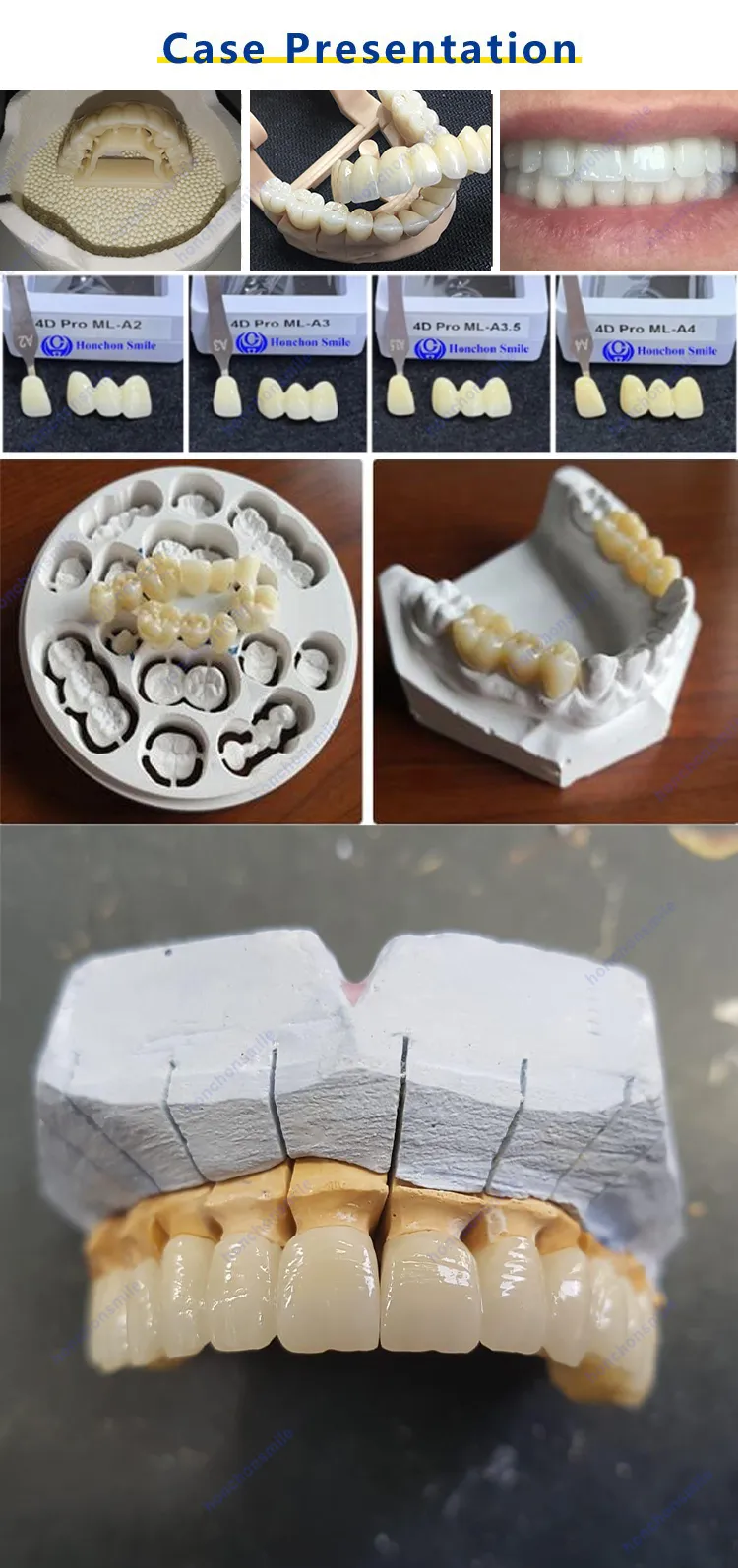

Our factory provides three major categories: multi-layer, pre-colored, and white blocks, and 15 different types of CAD and CAM zirconia blocks. For more information, please click here to learn more about zirconia blocks.

| Product Type | Translucency | Strength | Color | Recommended Main Application |

|---|---|---|---|---|

| HT plus | 40% | 1350 MPa | White | Posterior & long bridge |

| ST plus | 42% | 1200 MPa | White | Posterior & bridge |

| SHT | 46% | 1000 MPa | White | Posterior, anterior & bridge |

| UT | 49% | 650 MPa | White | Anterior |

| HTC | 40% | 1350 MPa | 16 shades | Posterior & long bridge |

| STC | 43% | 1100 MPa | 16 shades | Posterior & bridge |

| UTC | 49% | 650 MPa | 16 shades | Anterior |

| STML | 42% | 1100 MPa | 16 shades | Full contour & bridge |

| SHTML | 46% | 1100 MPa | 16 shades | Full contour & bridge |

| UTML | 49% | 650 MPa | 16 shades | Anterior |

| 3D-Plus ML | 45%–57% | 1050–700 MPa | 16 shades and BL | All |

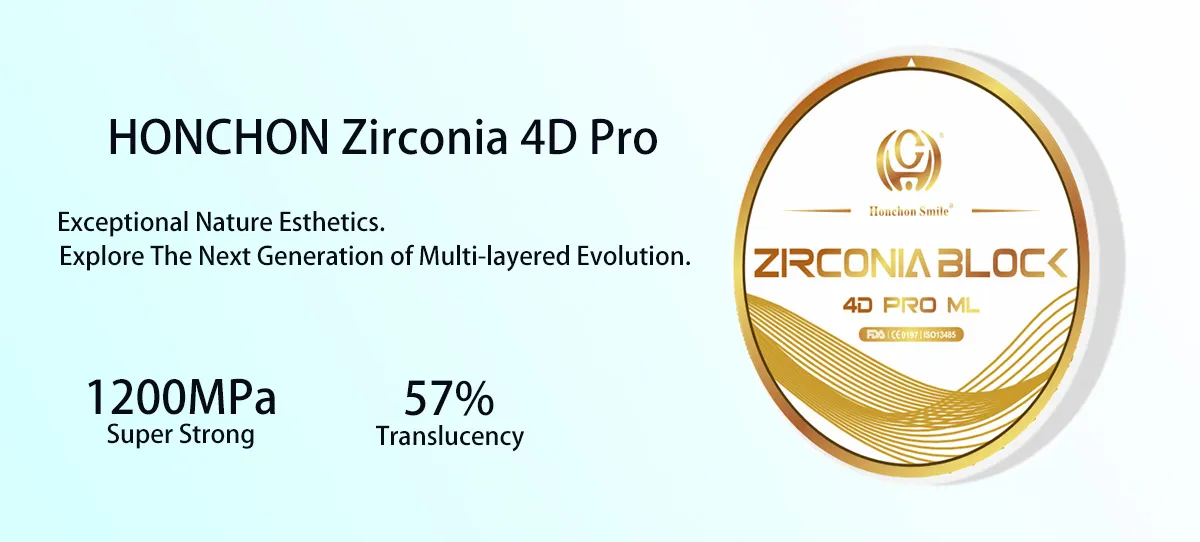

| 4D-Plus ML | 43%–55% | 1200–700 MPa | 16 shades and BL | All |

2. Advantages of CAD/CAM Zirconia Block

High strength: Zirconia blocks have excellent flexural strength (up to 1350 MPa), which ensures the stability of the restoration over time during use.

Aesthetics: Provides high light transmission and blends perfectly with natural teeth, especially for anterior restorations.

Compatibility: Compatible with mainstream CAD/CAM systems (e.g., Wieland/Zirkonzahn/Amann Girrbach, etc.), adapting to different equipment needs.

Wear resistance: Zirconia blocks have high hardness and wear resistance to meet the needs of long-term use.

Pre-colored and multi-layer design: Pre-colored zirconia blocks and multi-layer zirconia blocks are designed to provide natural color transitions and reduce the need for artificial dyeing.

3. Material of CAD/CAM Zirconia Block

| Composition | Content |

|---|---|

| Zirconia and stabilizers (ZrO₂ + Y₂O₃ + HfO₂ + Al₂O₃) | ≥ 99.0% |

| Yttrium oxide (Y₂O₃) | 4.0% – 10.0% |

| Hafnium oxide (HfO₂) | ≤ 5% |

| Aluminum oxide (Al₂O₃) | ≤ 0.1% |

| Other oxides (Fe₂O₃, Er₂O₃, MnO) | ≤ 0.9% |

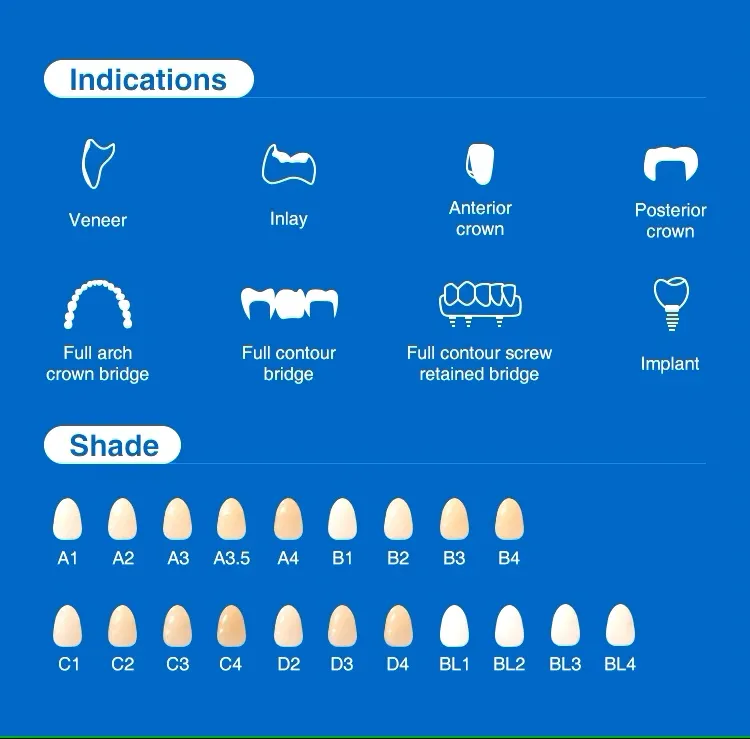

4. Application of CAD/CAM Zirconia Block

CAD/CAM Zirconia blocks are widely used in the following restorative dental applications:

Single crown restorations

Bridge restorations

Inlays and veneers

All-ceramic restorations

5. Sintering Curve of CAD/CAM Zirconia Block

The sintering curve is an important factor in optimizing the properties of zirconia materials. Typical sintering curves for CAD/CAM zirconia blocks are shown below:

Sintering temperature: 1530°C

Sintering time: Typically 1-2 hours, depending on the series of zirconia blocks.

Rate of temperature rise and fall: The recommended rate of temperature rise is 5°C/min, and the rate of temperature fall is 2°C/min to ensure the densification and homogeneity of the material.

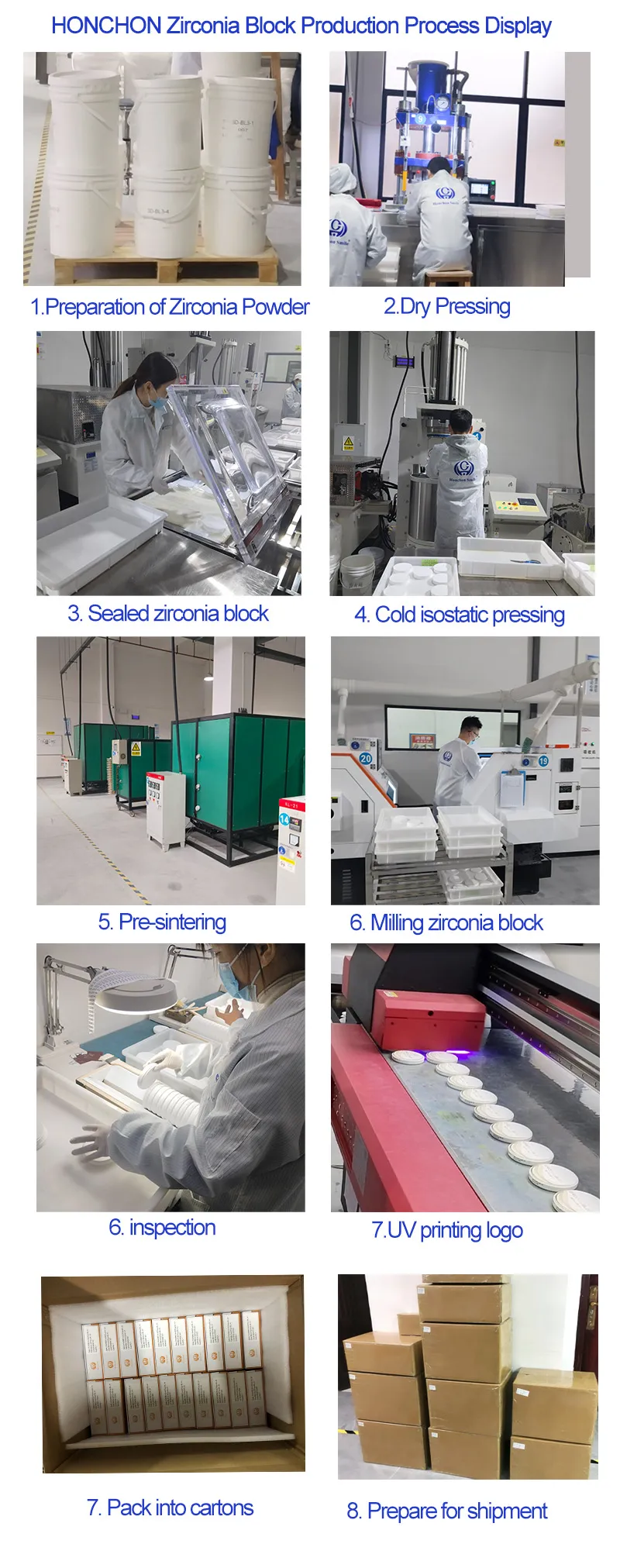

6. Process of CAD/CAM Zirconia Block

Raw material preparation: Selection of high-quality zirconia powder and other additives to ensure the purity and stability of the material.

Molding: Zirconia powder is molded into the desired shape through a dry pressing process.

Sintering: The molded zirconia blanks are put into a sintering furnace and sintered at a high temperature to improve their strength and denseness.

Surface treatment: The surface is polished according to different needs to improve the aesthetic effect and processability.

7. How to Cooperate with Us

We offer flexible cooperation models, including OEM/ODM services. The steps to cooperate with us are as follows:

Initial communication: Contact us and tell us your needs or product customization requirements.

Quotation and Sample Confirmation: Provide a detailed quotation and send samples for testing according to your requirements.

Order Production: After confirming the samples, formally place the order for production arrangement.

Delivery and after-sales service: Deliver on time, ensure smooth delivery, and provide technical support and after-sales service.

8. Our Certifications

Our CAD/CAM zirconia block products have passed several international certifications to ensure that they meet the quality standards of the global market:

ISO 13485: Quality Management System Certification, ensuring that production and services meet international standards.

CE certification: Compliance with product quality and safety requirements for the European market.

FDA Certification: Compliance with medical device certification standards for the U.S. market.

9. Our Factory

Our factory is located in Changsha, Hunan Province, China, with advanced production facilities and strict ISO13485 quality control system. Through continuous technological innovation and efficient production management, we ensure to provide customers with stable and high quality products. We welcome customers to visit our factory to learn more about our production process and capabilities.

10. FAQ

Q1: What are the applicable equipments for CAD/CAM zirconia blocks?

A1: Our CAD/CAM zirconia blocks are compatible with most of the major CAD/CAM systems on the market, such as Wieland/Zirkonzahn/Amann Girrbach, etc. We have a wide range of CAD/CAM systems available.

Q2: How to determine the right zirconia block series?

A2: If you need high strength and aesthetic effect, we suggest you to choose pre-colored or multi-layer zirconia blocks; if you have special color requirements, you can choose white zirconia blocks for post-dyeing.

Q3: Can I customize the size of zirconia blocks?

A3: Yes, we provide customized service, we can adjust the size and shape according to your needs.

11. CAD/CAM Zirconia Block Packaging

Our CAD/CAM zirconia blocks are packaged in a safe and environmentally friendly way to ensure that the product is not damaged during transportation. Each zirconia block is precisely packed to ensure that it reaches the customer in perfect condition. The packaging materials comply with international environmental standards and are easy to store and transport.

.jpg)