Zirconia Immersion Dyeing Technology: Enhancing Color Stability and Efficiency in Dental Restorations

2025-07-14

1. Introduction

As the demand for high-quality dental restorations grows, zirconia has become one of the most widely used materials in prosthodontics. It offers a combination of high strength, biocompatibility, and durability. However, its naturally milky white appearance limits its aesthetic application without further coloring treatment.

Traditional methods—such as external ceramic veneering or superficial liquid dyeing—either require extensive tooth preparation or lack long-term color stability. This article introduces a zirconia immersion dyeing process designed to improve efficiency, color uniformity, and longevity—making it ideal for large-scale dental manufacturing.

2. Current Challenges in Zirconia Dyeing Technologies

2.1 Complex Process and Long Dyeing Cycle

Many current methods require multiple steps—soaking, brushing, drying, and sintering—which can take over 12 hours in total. Manual steps (e.g., brushing on dye) reduce uniformity and increase labor intensity.

2.2 Color Durability Issues

Superficial dyeing fails to penetrate deep into zirconia, causing color fading or inconsistency after grinding or wear. Surface-only colorants are also more prone to contamination or degradation over time.

2.3 Lack of Industrial Suitability

Gradient dyeing methods can reproduce enamel-like effects but are difficult to standardize and scale, limiting their adoption in automated production lines.

3. Improved Zirconia Immersion Dyeing Process: Step-by-Step

This improved method introduces an infiltration-based immersion technique, offering deeper and more uniform coloring, with enhanced process control.

Process Overview

| Step | Description |

|---|---|

| 1. Pre-sintering | Zirconia is partially sintered at 1250–1300°C for 15–30 minutes. |

| 2. Grinding | Pre-sintered blocks are milled into the desired shape. |

| 3. Surface Cleaning | Debris is removed to enhance dye contact. |

| 4. Dye Immersion | Zirconia is soaked in a dye solution at 35–50°C for 30–45 seconds. |

| 5. UV Drying | Exposed to UV light (350–400 nm) for 15–20 seconds to stabilize surface coloring. |

| 6. Final Sintering | Fully sintered at 1550–1580°C for 30–45 minutes, then cooled gradually to room temp. |

Key Innovation: Ultrasonic Dye Penetration

To ensure uniform infiltration, ultrasonic equipment is used during the dye immersion phase. The vibrations help the dye penetrate deep into the microporous pre-sintered zirconia, achieving a longer-lasting result.

4. Dye Composition and Chemistry

The dye solution includes a blend of rare earth ions to closely mimic natural tooth shades:

Coloring Ions: Er³⁺ (erbium), Pr³⁺ (praseodymium), Co²⁺ (cobalt)

Concentration: 0.05–0.20 mol/L

Additives: 0.5–0.8 wt% Polyethylene Glycol (PEG), 0.2–0.5 wt% Sodium Oxide (Na₂O)

PEG increases the wettability and spread of the dye, while sodium oxide enhances dye adherence and thermal stability.

5. Benefits of the New Zirconia Dyeing Process

| Feature | Benefit |

|---|---|

| Uniform Dye Penetration | Even color distribution in 3D structures |

| Shorter Processing Time | Full cycle reduced to under 2 hours |

| Natural-Looking Shade | Replicates enamel and dentin gradients |

| Stable Under Sintering | No significant color loss during high-temp sintering |

| Industrial Scalability | Supports batch production with consistent results |

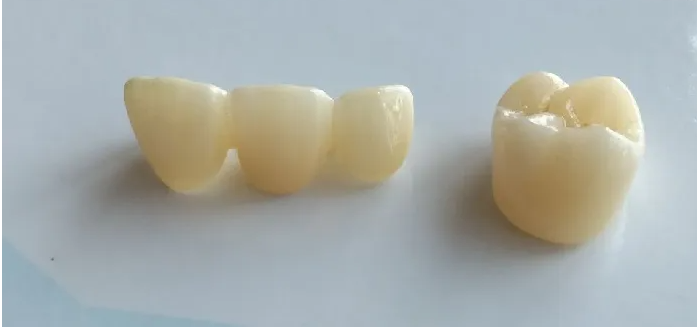

This method is especially suitable for multilayer or full-contour zirconia restorations used in anterior and posterior teeth.

6. Application Scenarios

Full contour crowns

Bridge restorations

Monolithic zirconia blocks

OEM customized shade systems

Dental labs with CAD/CAM workflows

7. Conclusion

The improved zirconia immersion dyeing technology solves many limitations of traditional methods, offering an efficient, consistent, and scalable solution for modern dental manufacturing. By integrating ultrasonic infiltration, optimized dye chemistry, and controlled sintering, this method provides long-lasting, natural-looking results.

This process not only enhances aesthetic outcomes but also increases production efficiency—making it a promising solution for industrial dental labs and zirconia block manufacturers.

Related Product

Looking for high-quality, pre-shaded zirconia blocks compatible with your CAD/CAM system?

Explore Our STP/SHTP Multilayer Zirconia Blocks →

References

Gao Yong, Liu Ce, Wang Yunqiang, et al. Preparation method of zirconia dental materials, CN112661504A, 2021.

Chen Liangxing, Liang Pengwei, Wang Hao, et al. Zirconia immersion coloring method, CN109734444A, 2019.