Analysis of factors affecting the color of full zirconium teeth

2024-05-07

Since the Shanghai Exhibition in October 2010, the concept of full zirconium teeth has begun to appear in the domestic market. After several years of joint efforts by material, equipment, software manufacturers, denture processing plants and clinicians, full zirconium teeth have become the first choice for functional restoration of dentures. Material. With the development of materials and processes, the clinical requirements for the color and transparency of full zirconium teeth are gradually increasing. Here, honchon smile will summarize and share many years of training experience in full zirconium teeth process, as well as solutions to problems encountered in the process. for everyone,

1. Selection of materials: staining solution and zirconia porcelain block

When making full zirconium teeth, the choice of staining solution and porcelain block manufacturer and type is crucial. It is recommended that the porcelain block and staining solution be made by the same manufacturer, and that matching staining solution and dyeing process be used. When the same staining solution is used with porcelain blocks from different manufacturers, the color of the crowns after sintering will be different; when the same staining solution is used with different types of porcelain blocks, the color of the crowns will also be different after sintering.

Regarding the dyeing liquid: first, the dyeing liquid used must be within the validity period; secondly, it must be stored according to the storage conditions required by the manufacturer; in addition, the dyeing liquid must not be contaminated during use.

Regarding porcelain blocks: It is recommended to choose materials with better permeability. If you use honchon smile porcelain blocks to make full zirconium teeth, you can choose between ST (super transparent) and ST color (color transparent), combined with 16-color staining solution.

2. Internal dyeing method: soaking or painting

(1) Soaking method:

Soaking time: honchon smile dyeing solution and ST porcelain block are soaked for 2-5 minutes to have the same color. After 5 minutes, the color will slightly deepen as the soaking time increases, but the deepening color is not obvious;

Number of soaked crowns: If the crowns are soaked too much, the crowns will be in close contact or overlap, which will affect the penetration of the staining solution and affect the color of the crowns after sintering;

Soaking solution usage time: During the soaking process, the shedding of zirconium powder and the evaporation of water in the dyeing solution will affect the color of the dyeing solution to become darker or lighter. It is recommended that before staining the whole zirconium tooth, the dust on the surface and inside the crown must be removed. The soaking container must be covered during the soaking process of the crown.

(2) Brushing method:

The brushing method, tools, and amount of staining solution will all affect the color of the sintering crown. You should refer to the manufacturer's recommended painting methods and constantly sum up experience during use.

If you use the soaking + brushing method, you need to pay attention to the method and time of drying the crown after soaking, as well as the brushing method after drying.

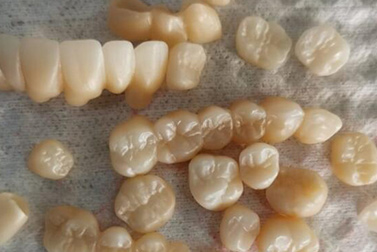

Staining sintered crowns using different staining methods

3. Crown thickness

The same dyeing method has different colors for crowns with different thicknesses. For example, 0.6mm, 1.5mm, and 3.0mm crowns are also soaked in A3 color dyeing solution for 4 minutes. After sintering, the color of 0.6mm crowns is lighter than that of A3 crowns and 1.5mm crowns. The color is close to A3 color, and the color of 3.0mm crown is darker than A3 color. Similarly, when a set of bridges is soaked in A3 color and sintered, the color of the crown is close to or lighter than A3 color, while the bridge body will be darker than A3 color. Therefore, it is recommended to use the soaking + painting method when dyeing the bridges.

(In the above picture, you can see that the crowns on both sides are lighter in color and the pontic in the middle is darker)

4. Equipment selection: sintering furnace, porcelain furnace

There are many manufacturers of sintering furnaces on the market. The silicon-molybdenum rods, refractory materials, internal structure of the sintering furnace, program settings, crucibles and sintering beads used in sintering are different from each manufacturer's sintering furnaces, which will lead to the formation of zirconia crowns. The sintering environment in the sintering furnace is different, which ultimately affects the color deviation of the sintering crown. In addition, as the use time of the sintering furnace increases and routine maintenance is not done properly, the sintered crowns will become contaminated and appear blue-green or have white spots on the surface. It is recommended to regularly clean the falling dust in the sintering furnace chamber and use the cleaning procedure regularly. Burn the furnace, replace the sintering beads regularly, and cover the crucible with the lid during sintering. In addition, in the past two years, customers have often experienced premature sintering of their crowns (poor crown transparency and light color). It is recommended to contact the sintering furnace manufacturer for assistance at this time.

The color of the glaze and sintering of different manufacturers' porcelain furnaces is slightly different (Ivoclar is slightly yellow, VITA is slightly red), and the different brightness of the crown surface affects the number of times the crown is put into the furnace; the more times the crown is put into the furnace, the color of the crown will be slightly lighter. .

5. Sintering curve

Carry out sintering according to the sintering temperature and curve required by the dyeing solution and porcelain block manufacturers.

Different sintering temperatures and sintering curves result in different colors of sintered crowns.

For example, the color of Altron ST colored porcelain blocks is accurate according to the sintering curve and sintering temperature of 1530°C (heat preservation for 2 hours) required by the manufacturer. When the sintering temperature is >1530°C, the color of the crown will be lighter; when it is <1480°C, the color of the crown will also be lighter and has poor permeability and strength (the crown is not cooked); when the sintering temperature is between the two temperatures, the crown will be sintering The color is darker and the permeability is slightly different.

In addition, some sintering furnaces will have temperature differences. When using, the maximum temperature of the sintering curve should be reasonably adjusted according to the color of the sintering crown to ensure that the color of the sintering crown is normal.

6. Other factors

(1) Differences in the light source used for color comparison and individual color recognition will affect the final crown color.

It is recommended that the light source used by technicians in the processing factory should be consistent with the light source used in clinical colorimetry. Doctors who have high requirements for color should try to provide pictures for reference to the processing factory. The processing factory should focus on cultivating and training the color sensitivity of porcelain lamination and glazing technicians.

(2) Differences in colorimetric reference materials

Color guides of different brands, production batches, and usage times have different colors.

Recommendation: Try to use the same manufacturer and batch of color guides as clinical use; if the colors of the color guides are inconsistent, try to let the technician know the color difference.

(3) Crown design capabilities

When the crown bite is too high, the color of the crown will easily become lighter or white after trimming, because the dyeing solution on the market penetrates zirconia to a depth of 2.5~3.0mm. If the crown dyeing method is incorrect, the penetration rate of the dyeing solution will decrease. When the crown shape and occlusal relationship are adjusted after sintering, the color will become lighter and whiter.

It is recommended that designers reasonably design the crown shape and occlusal relationship based on clinical requirements and equipment processing conditions, and at the same time, try to make the dyeing liquid completely penetrate into the crown when dyeing (generally, the dyeing liquid on the crown can fully penetrate, and each side of the pontic can penetrate 2.5~ 3.0mm).

To sum up, the perfect color and transparency of a full zirconium tooth depends on our technicians’ familiarity with materials, software, and equipment, mastery of production techniques, and cooperation between medical technicians and technicians in each process, just like A plate of delicious food with full color, aroma and flavor depends on the chef's understanding of the ingredients and cooking skills and control of the heat.