Product Overview

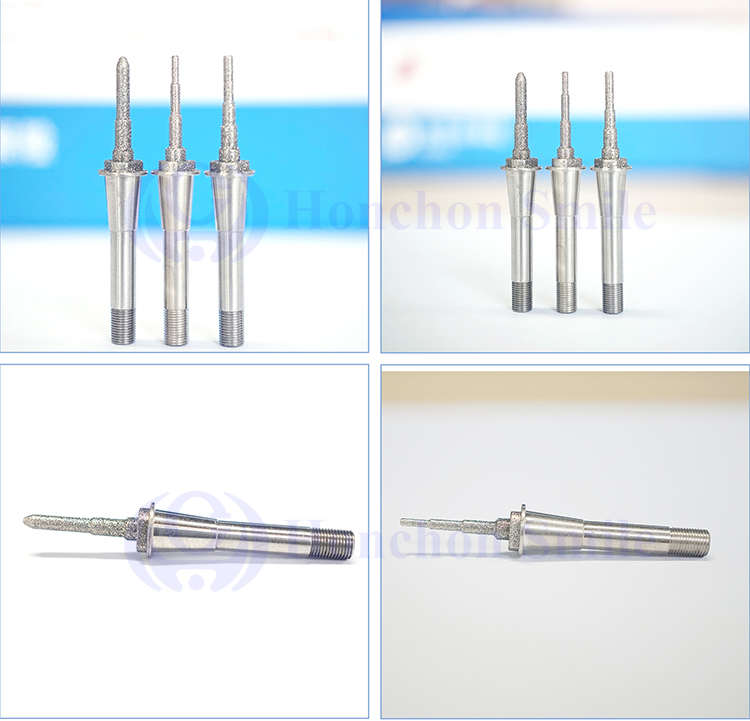

These burs are made to fit MCXL milling machines, used in many dental clinics and labs. They can be used to mill common materials like lithium disilicate (e.g., E.max), zirconia, and PMMA. With high cutting precision and long lifespan, they help dentists and technicians get clean, accurate restorations.

Main Features

Accurate cutting: Sharp edge design for smooth and precise milling

Long service life: Durable coating extends tool usage time

Low heat: Works with less heat, reducing material cracks or burns

Stable performance: Consistent results for daily clinic or lab use

Easy to use: Plug and mill – no extra setup needed

Material & Coating

Material: High-quality tungsten steel

Coating Types:

DC coating – for zirconia

Diamond coating – for lithium disilicate

No coating – for PMMA or wax

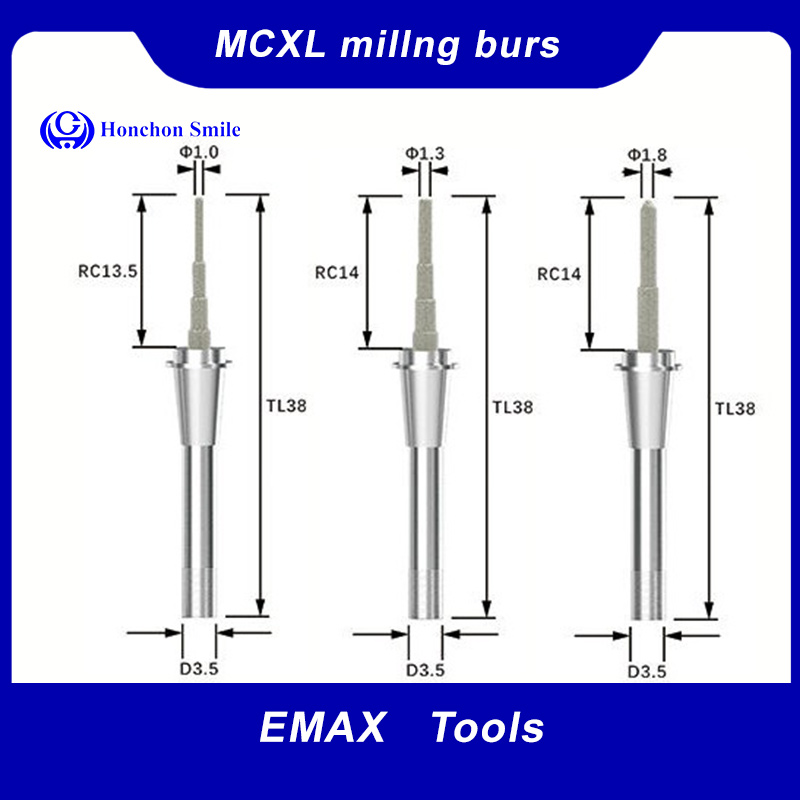

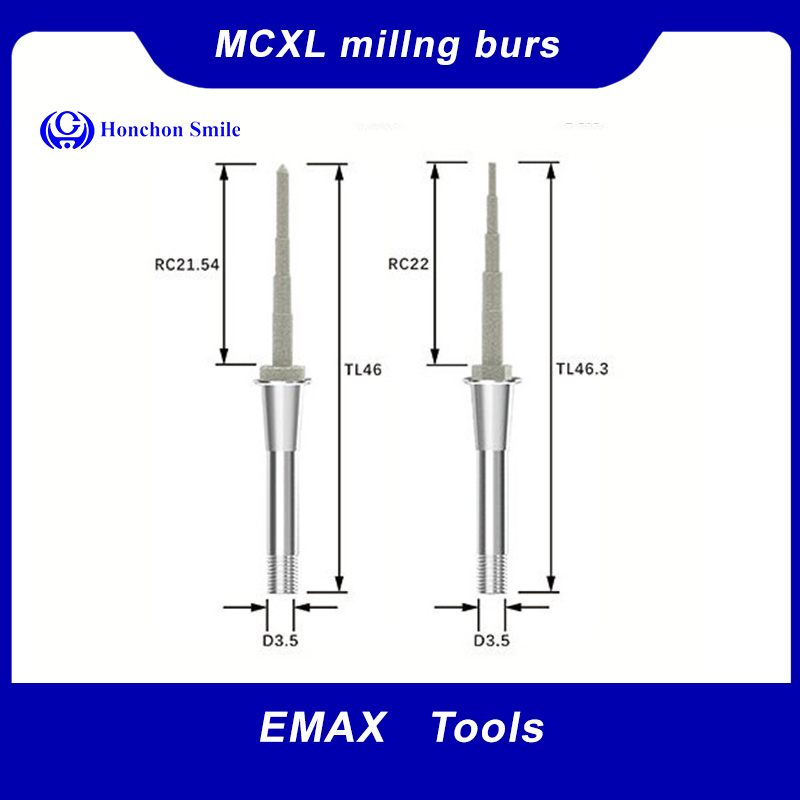

Sizes Available

| Bur Type | Diameter Options | Use Material |

|---|---|---|

| Step Bur | 1.0mm / 2.0mm | Zirconia, PMMA |

| Cylinder Bur | 1.2mm / 2.5mm | Glass ceramic, PMMA |

| Pointed Bur | 1.0mm | PMMA, detailed parts |

Custom sizes also available on request.

Application

These burs are compatible with:

CEREC MCXL

inLab MCXL

Other similar chairside milling units

Suitable for:

Inlays, onlays

Crowns and bridges

Veneers

Temporary restorations

Packaging & Order Info

MOQ: 10 pcs

Lead time: 3–5 working days for stock items

OEM support: Logo engraving, color ring customization available

Samples: Small test orders accepted

Shipping: DHL/FedEx/UPS or your forwarder

Contact Us

Looking for burs that fit your MCXL system?

We’re here to help.

info@honchon.com

www.honchon.com

.jpg)