Product Overview

These milling burs are made to fit UP3D CAD/CAM dental systems. They are designed for milling zirconia blocks, PMMA, wax, and glass ceramics. With strong cutting ability and long service life, they help dental labs and clinics complete restorations more efficiently and precisely.

Key Features

High precision – Ensures smooth surface and accurate fit

Durable coating – Longer life, stable performance

Low vibration – Reduces chipping or breaking during milling

Multi-material use – One set supports various dental materials

Easy installation – Plug and play with UP3D systems

Material & Coating Options

| Material | Suitable For | Coating Type |

|---|---|---|

| Tungsten Carbide | Zirconia | DC / RC / DLC |

| Tungsten Carbide | PMMA & Wax | Uncoated |

| Tungsten Carbide | Glass Ceramics | Diamond Coated |

DC/DLC/RC coatings – Ideal for zirconia milling

Diamond coating – Best for lithium disilicate

Uncoated – For PMMA and wax

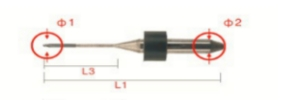

Common Sizes

CADCAM System | Function | Coating | Shaft Φ2/mm | Total Length L1/mm | headmeter Size/Φ1mm | ||

| Round | Flat | Toric | |||||

| UP3D/5D | Milling Zirconia | DLC/RC/DC | Φ4mm | 50 | 2.0/1.0/0.6/0.3 | 1.0 | / |

| Milling Emax | DC | Φ4mm/3mm | 45 | 2.5/1.0/0.6 | / | / | |

| Miling Metal | / | / | / | / | / | / | |

| Miling PMMA | / | Φ4mm | 50 | 2.0/1.0/0.6/0.3 | / | / | |

Custom sizes and shapes available upon request.

Compatibility

Fully compatible with:

UP3D P series milling machines

UPCAM software workflow

Supports 3-axis and 5-axis machines in the UP3D system

Order Details

MOQ: 10 pcs per size

Sample available: Yes

Lead time: 3–7 working days

OEM/ODM: Custom packaging and laser engraving available

Shipping: DHL, FedEx, or by sea/air as required

Let’s Work Together

We support OEM/ODM production and distributor partnerships. Whether you're a lab, distributor, or equipment provider, we can offer reliable support and high-quality tools to help grow your business.

Email: info@honchon.com

Website: www.honchon.com

.jpg)