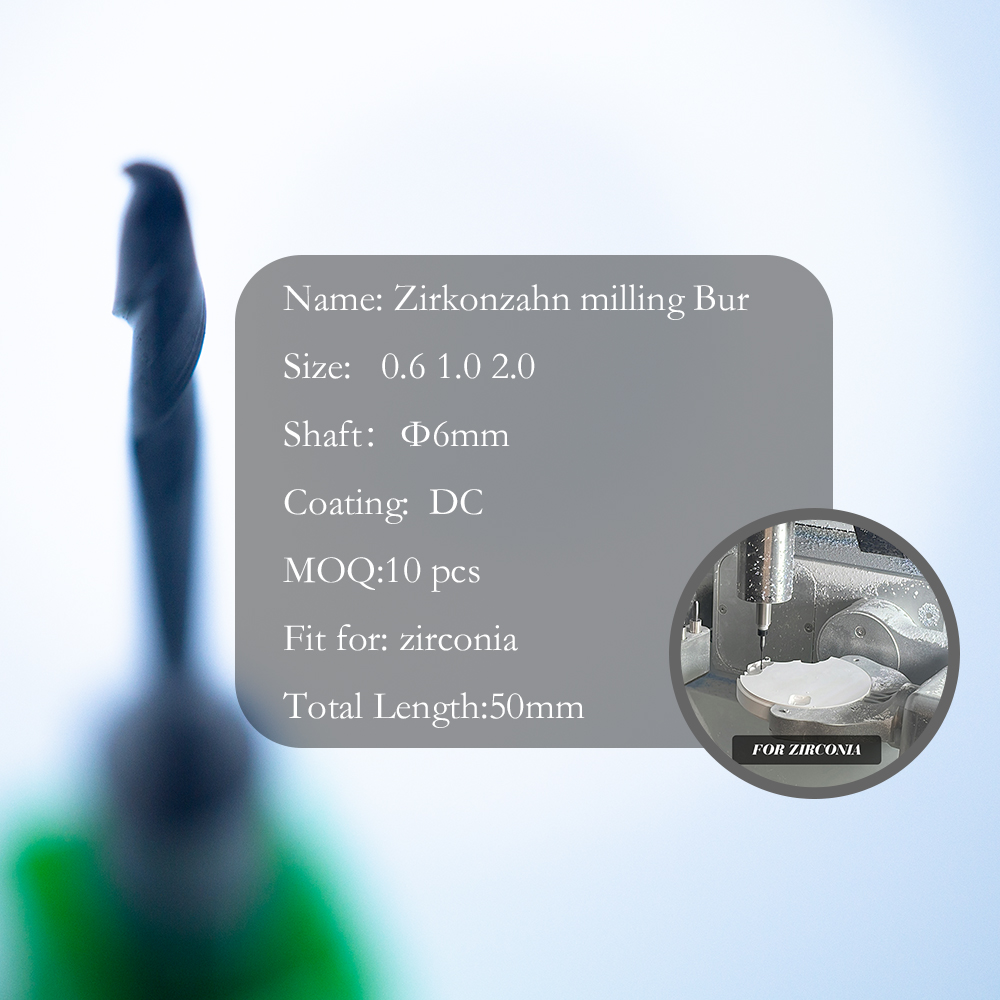

1. Product Overview

Our dental milling cutters are specially designed to be fully compatible with Zirkonzahn milling systems. Whether you are producing zirconia crowns, bridges, or full-arch restorations, these cutters provide reliable performance and precision. They are ideal for dental labs using Zirkonzahn M1, M2, or M5 systems.

2. Key Features

Fully compatible with Zirkonzahn CAD CAM machines

High cutting accuracy for clean margins and smooth surfaces

Long lifespan thanks to high-quality materials and coatings

Stable performance during long milling cycles

Suitable for zirconia, PMMA, wax, and other dental materials

3. Cutter Materials and Coating Options

We use premium tungsten carbide for the tool body, ensuring sharpness and durability.

Coating options include:

DC, RC, and DLC coating for zirconia milling

Diamond coating for glass ceramic materials

No coating for PMMA and wax

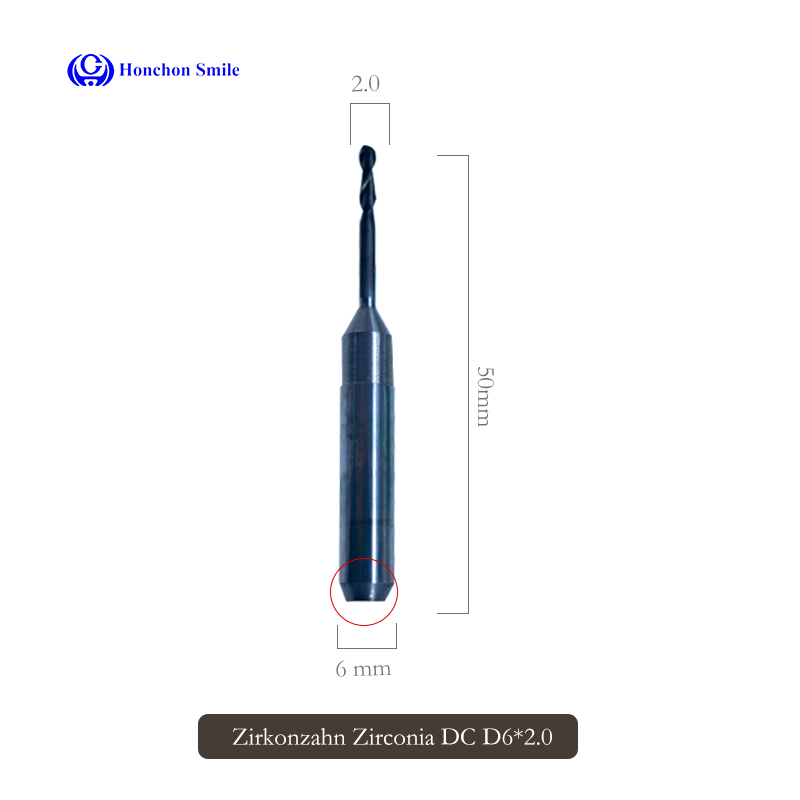

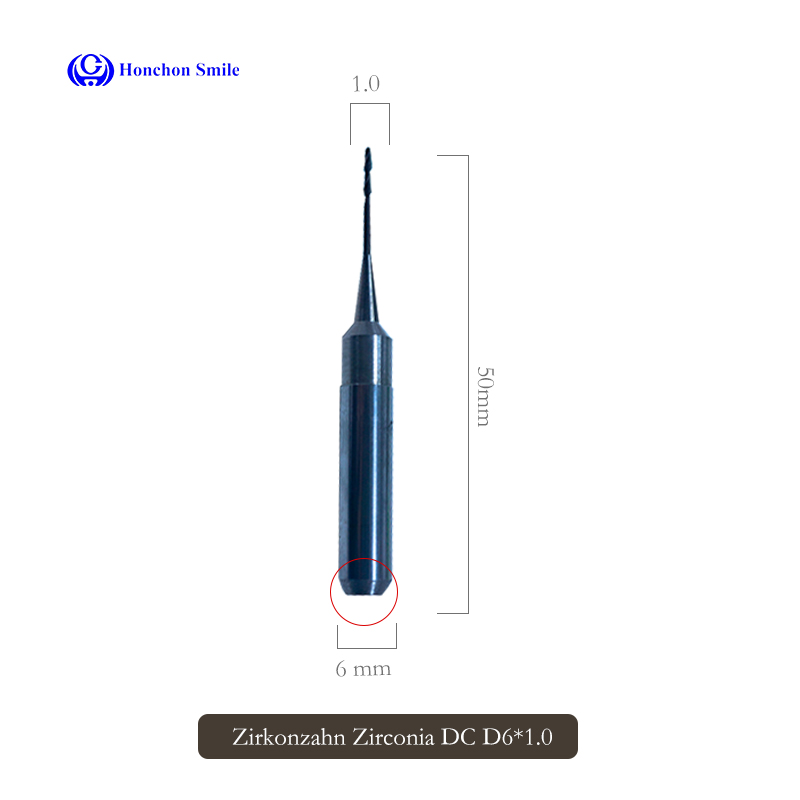

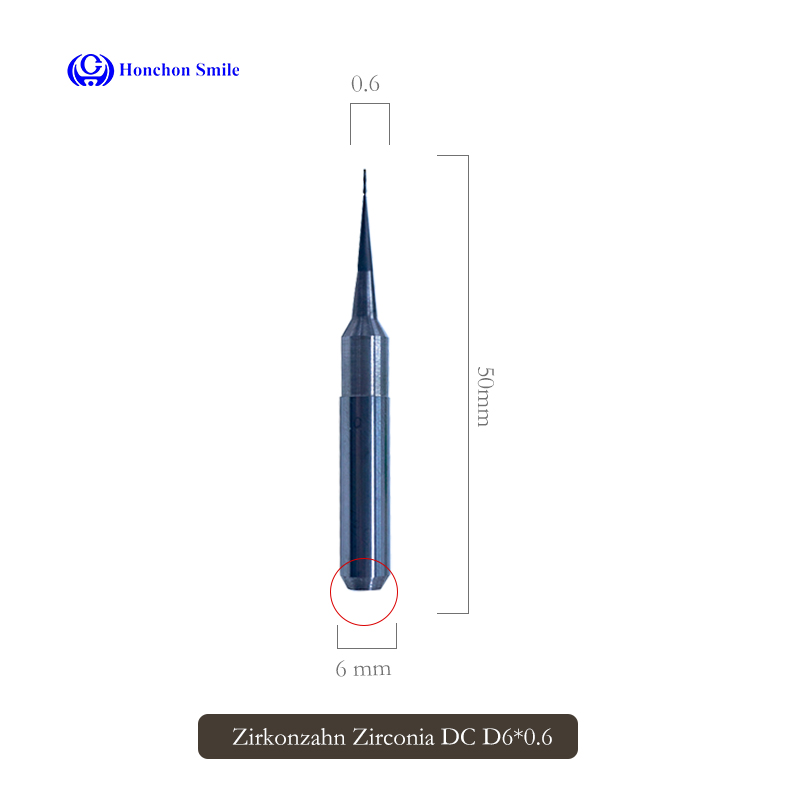

4. Specifications

Available in a range of common sizes:

Diameter: 0.6 mm, 1.0 mm, 2.0 mm, 2.5 mm

Types: flat end, ball nose, stepped cutter

Custom sizes and shapes can be made to fit your specific milling workflow.

5. Application

These milling cutters are suitable for:

Single crowns

Multi-unit bridges

Veneers

Implant abutments

Temporary restorations

6. OEM and Distributor Support

We provide OEM services and welcome long-term cooperation with dental labs, resellers, and equipment dealers. Private label, customized packaging, and sample support are available.

Need high-quality tools for your Zirkonzahn system? Contact HONCHON today to get a quote or free sample.

.jpg)