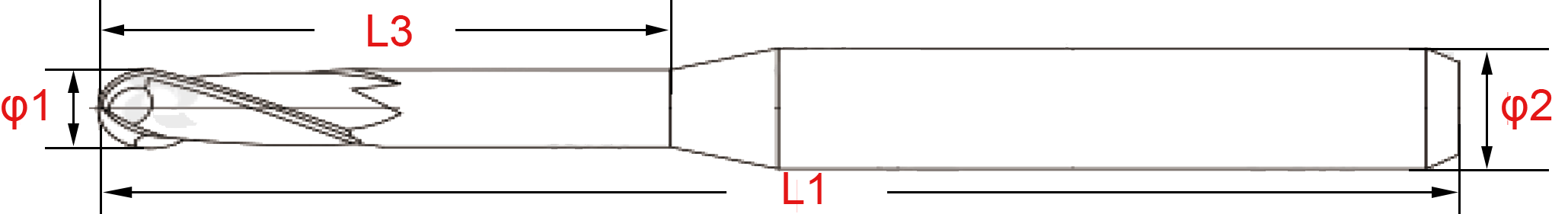

1. Product Overview

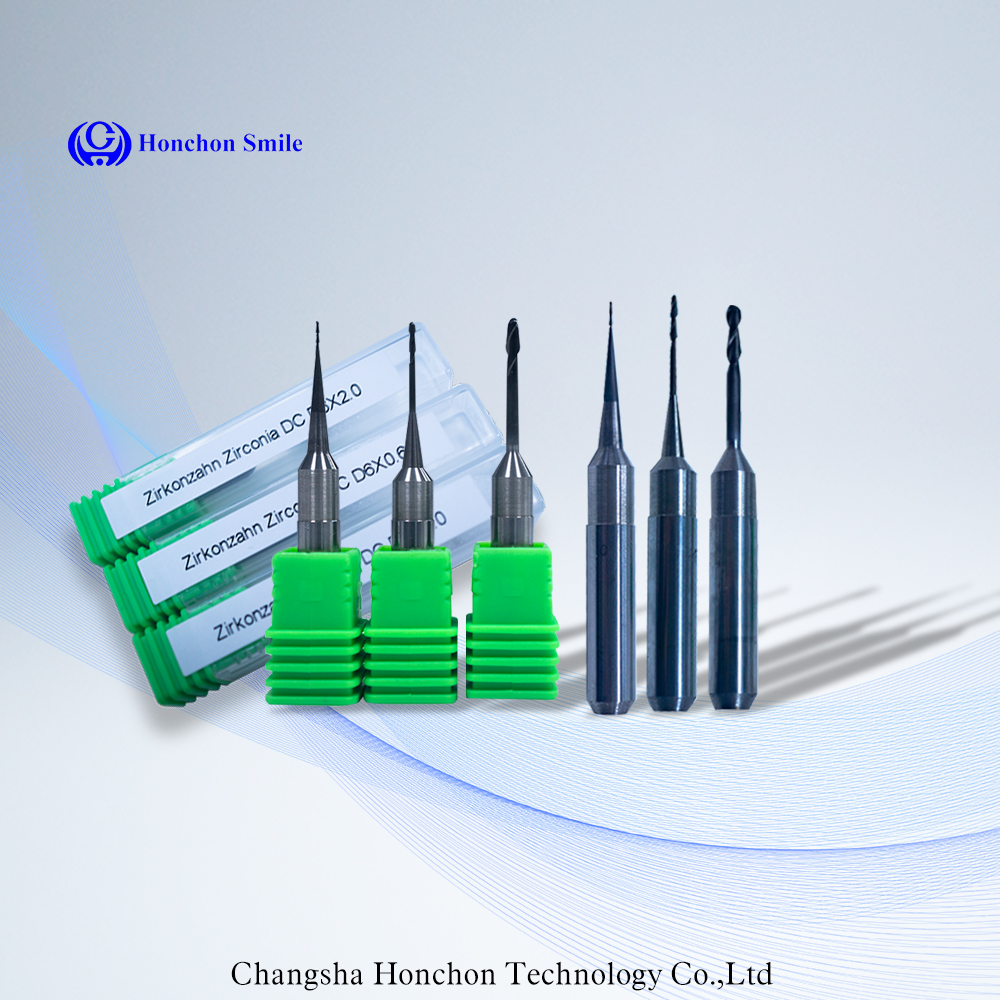

Changsha Honchon Technology Co., Ltd. offers a range of dental milling cutters designed for milling zirconia. Zirconia milling cutters come with different coatings, namely DLC/RC/DC, and are available in a variety of sizes to meet the different needs of our customers. With our dental milling cutters, you can achieve precise and efficient milling results.

2. Available sizes:

| Zirkonzahn Milling Bur for Milling Zirconia | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

| 0.5 | 57 | 3 | DLC/RC/DC |

| 1.0 | 57 | 3 | DLC/RC/DC |

| 1.5 | 57 | 3 | DLC/RC/DC |

| 2.0 | 57 | 3 | DLC/RC/DC |

| 3.0 | 57 | 3 | DLC/RC/DC |

| Zirkonzahn Milling Bur for Milling Zirconia | |||

| |||

| headmeter φ1 (mm) | Total Length L1 (mm) | Shaft φ2 (mm) | Type |

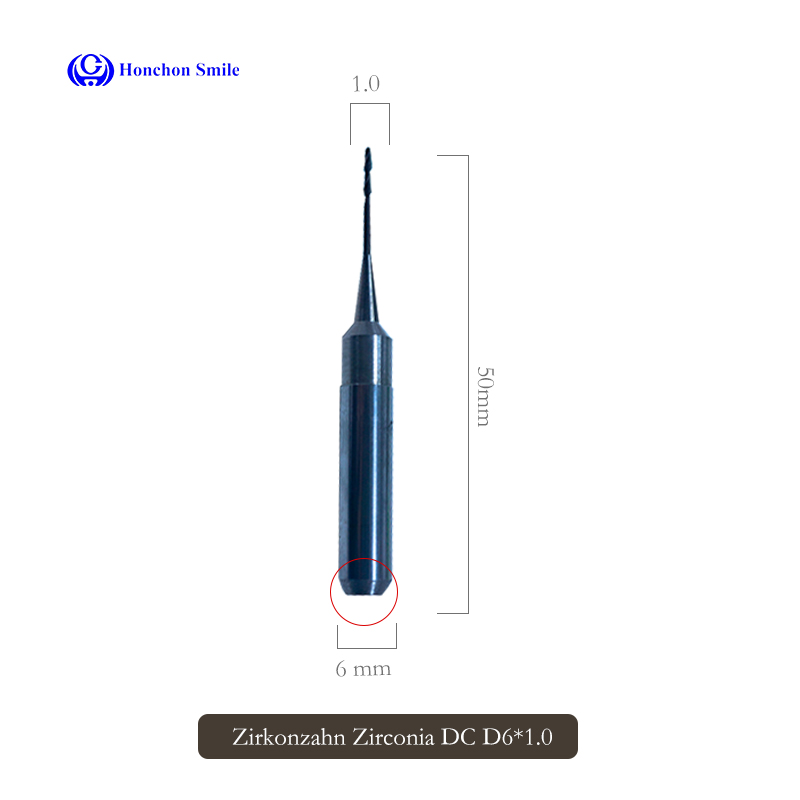

| 0.3 | 50 | 6 | DLC/RC/DC |

| 0.5 | 50 | 6 | DLC/RC/DC |

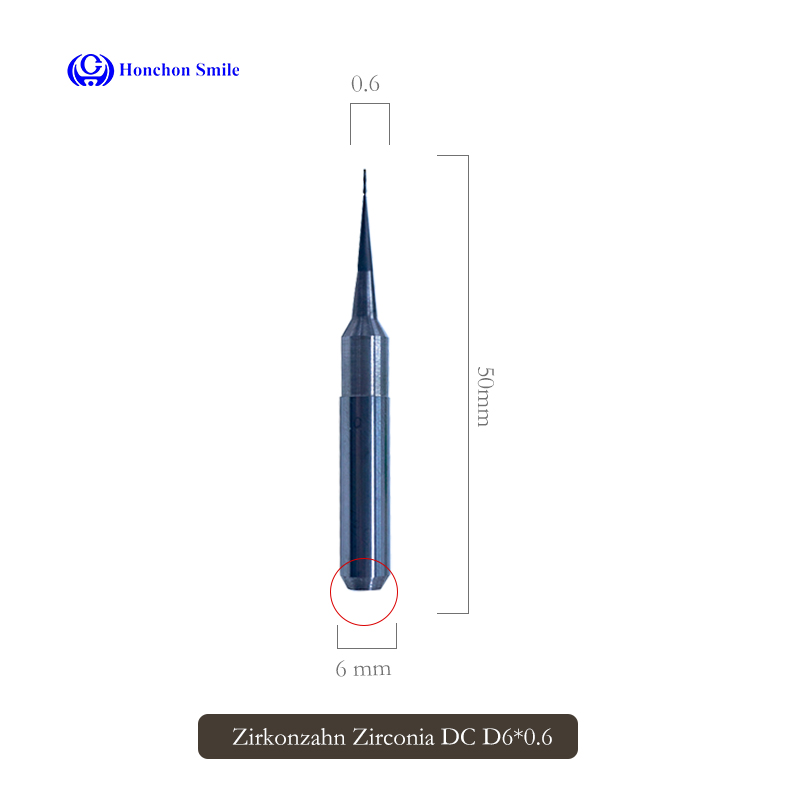

| 0.6 | 50 | 6 | DLC/RC/DC |

| 1.0 | 50 | 6 | DLC/RC/DC |

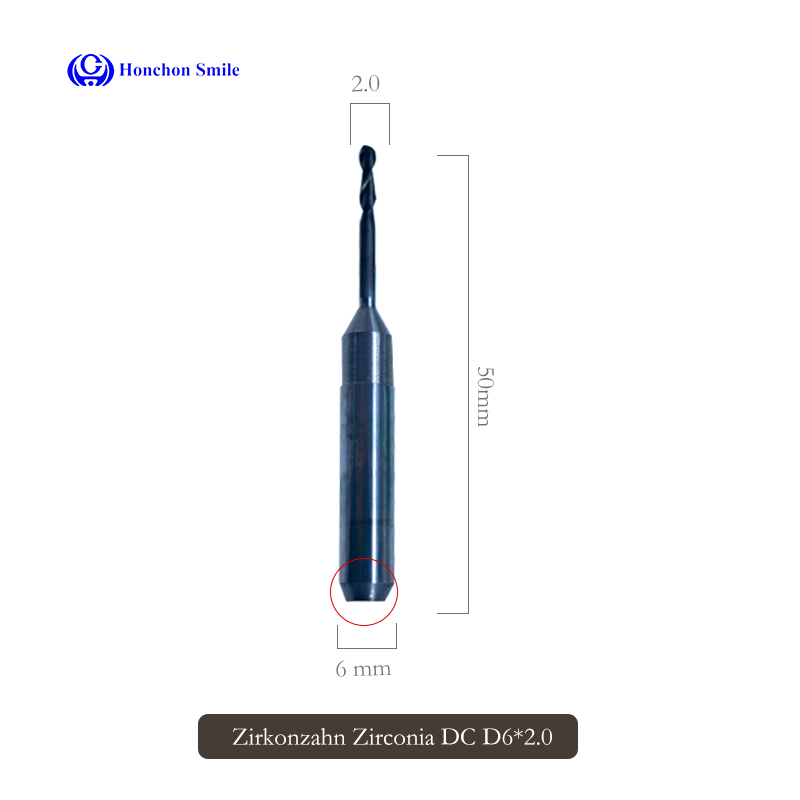

| 2.0 | 50 | 6 | DLC/RC/DC |

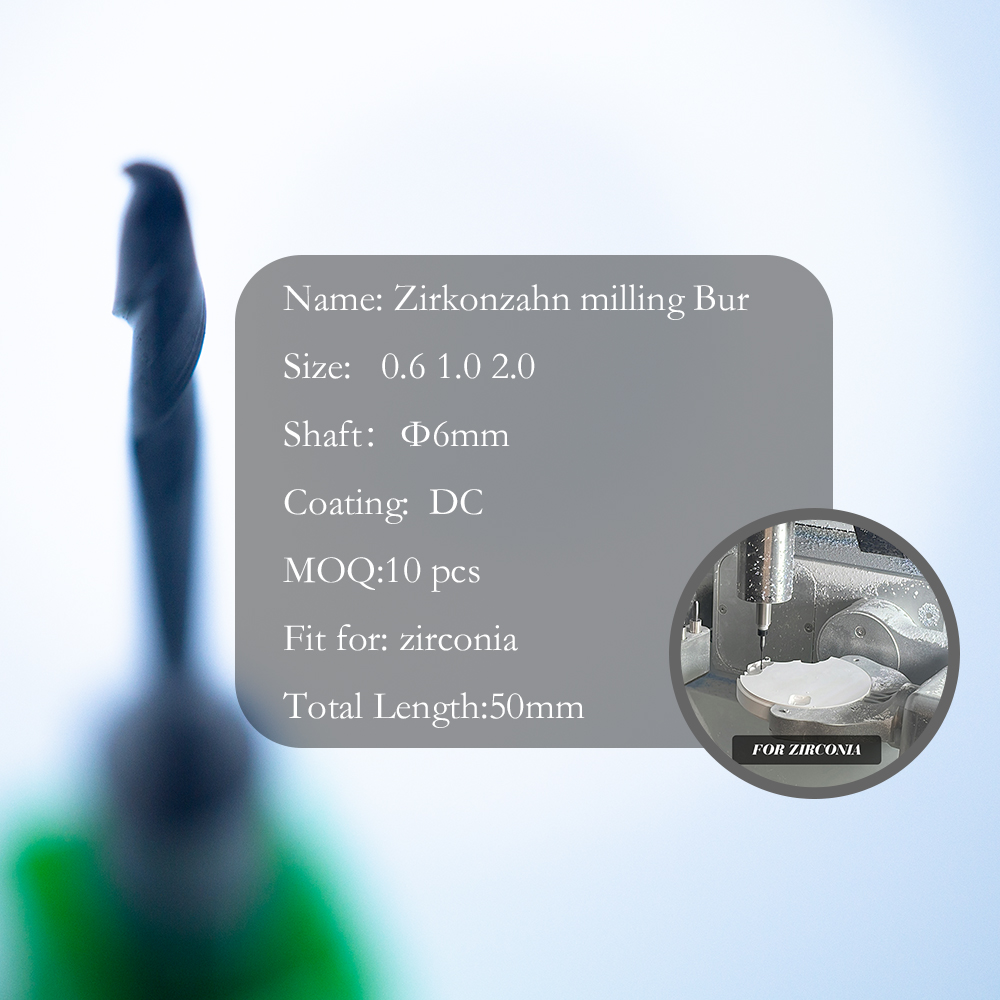

Some product displays

Product Features and Applications:

Our milling drill bits are 1:1 restored and are perfect replacements for original milling burs. They can not only guarantee milling performance, but also take into account economic applicability, save costs, and do not affect work efficiency. Our milling burs provide various coatings, such as DC, RC and DLC, which not only extend the service life of the drill bit, but also improve its milling efficiency, thereby achieving smooth and precise cutting.

Zirconia milling cutter is a special needle for milling zirconia, which is 100% compatible with Zirkonzahn machines. The zirconia milling cutter in our factory is 20% more durable than its peers, and has more outstanding milling performance. These evaluations are all from our customers, so please rest assured to purchase.

Production Details:

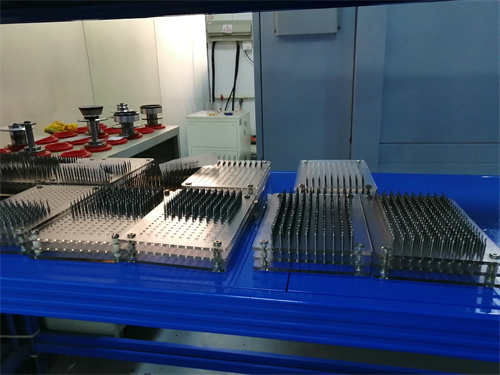

At Changsha Hongchuang Technology Co., Ltd., we use the most industry-leading manufacturing process. All production machines are imported from Europe, and the raw materials are also from high-quality suppliers in the industry. Our production line is ISO-certified, and all products have been inspected and qualified to ensure that customers can use them with confidence.

Product Qualification:

zirconia milling cutter in our portfolio undergoes rigorous testing and quality assurance protocols to meet and exceed industry standards.

Delivery, Shipping and Service:

We ensure a streamlined delivery process, with carefully packaged milling burs delivered quickly and safely to your doorstep. As some of the milling burs have very small heads, we stuff sponges in the packaging box to ensure that the milling burs are protected from damage during transportation.

Key Features

Fully compatible with Zirkonzahn CAD CAM machines

High cutting accuracy for clean margins and smooth surfaces

Long lifespan thanks to high-quality materials and coatings

Stable performance during long milling cycles

Suitable for zirconia, PMMA, wax, and other dental materials

Production Process:

At Changsha Honchon Technology Co., Ltd., we follow a meticulous production process to ensure the highest quality dental milling tools. The process involves the following steps:

Material Selection: We carefully choose high-quality materials that are durable and provide excellent milling performance.

Coating Application: Depending on the desired coating, the selected tools are coated with DLC, RC, or DC using advanced coating technologies. The coatings are applied uniformly and precisely to maximize their benefits.

Precision Machining: The coated tools undergo precision machining processes to achieve the required dimensions and cutting geometries. Our state-of-the-art machinery ensures accurate milling tool production.

Quality Control: Before the dental milling tools are packaged and shipped, they undergo rigorous quality control checks to ensure they meet our strict standards. This guarantees that you receive reliable and high-performing tools.

Important Usage Details:

To ensure optimal performance and longevity of our dental milling tools, it is important to pay attention to the following details during usage:

Proper Handling: Handle the tools with care to avoid any damage or breakage. Avoid dropping or mishandling the tools to maintain their integrity.

Correct Speed and Feed Rates: Use the recommended speed and feed rates while milling zirconia to achieve the best results. Operating outside the recommended parameters may affect the tool's performance and lifespan.

Regular Maintenance: Clean the tools after each use to remove any debris or residue. Additionally, periodic maintenance, such as sharpening or re-coating, should be considered to maintain the tools' cutting efficiency.

In conclusion, Changsha Honchon Technology Co., Ltd. offers high-quality Dental Milling Tools designed specifically for milling zirconia. With superior coatings, versatile size options, and customization services, our tools provide efficient and precise milling results for various dental applications. Following the recommended usage details will help you maximize the longevity and performance of our dental milling tools. Trust in our expertise and choose Changsha Honchon Technology Co., Ltd. for all your dental milling tool needs.

.jpg)