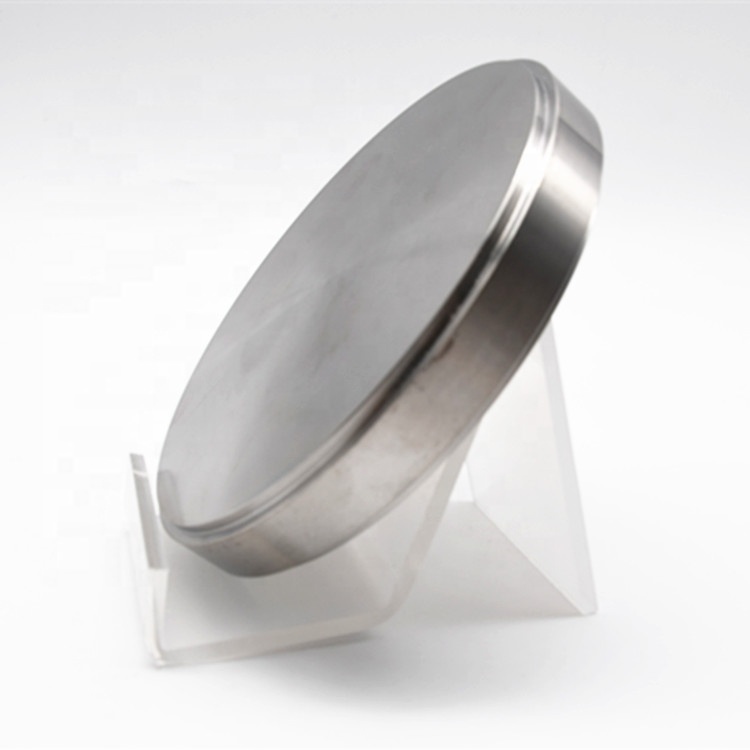

1.product Introduction

A dental titanium disc refers to a specialized dental material that is commonly used in the fabrication of dental prosthetics and restorative components. This disc is crafted from high-quality titanium, a biocompatible metal known for its durability and resistance to corrosion. Dental technicians use these discs as a foundational material for creating crowns, bridges, and other dental appliances. The use of titanium ensures that the resulting prosthetics are not only robust but also compatible with the human body, reducing the risk of adverse reactions. The dental titanium disc plays a crucial role in modern dentistry, contributing to the development of long-lasting and reliable dental solutions.

2.Advantages of Dental Titanium Disc

Biocompatibility:Titanium is a biocompatible material, meaning it is well-tolerated by the human body. This reduces the risk of allergic reactions or adverse responses, making it a suitable choice for dental applications.

Durability:Titanium is known for its exceptional strength and durability. Dental prosthetics and restorations crafted from titanium discs exhibit long-lasting performance, withstanding the challenges of daily wear and tear in the oral environment.

Corrosion resistance:Titanium has a high resistance to corrosion, ensuring that dental appliances made from titanium discs maintain their integrity over time. This resistance to corrosion is particularly important in the moist and acidic conditions of the oral cavity.

Lightweight:Despite its strength, titanium is a lightweight material. This characteristic is advantageous for dental prosthetics, as it contributes to the comfort of the patient by reducing the overall weight of the dental appliance.

3.Why Choose Us

Superior biocompatibility: Our zirconia-blanks boast exceptional biocompatibility, which is crucial for medical applications. They are hypoallergenic and won't cause adverse reactions when in contact with human tissues, ensuring safety and comfort for end-users.

Unmatched mechanical strength: Our zirconia-blanks offer superior durability and resistance to wear and tear. The high mechanical strength of zirconia means that your packaging tubes can withstand the rigors of transportation and handling, without compromising on the integrity of the contents.

Enhanced aesthetics and functionality: The smooth, glossy finish of zirconia adds a touch of elegance to your medicine packaging tubes. Moreover, the material's translucency allows for easy inspection of the contents, facilitating inventory management and reducing wastage.

Customizable solutions for unique needs: We understand that every medical product is unique, and so are your packaging requirements. Our zirconia-blanks can be customized to meet specific dimensions, shapes, and features, allowing you to create bespoke packaging solutions that perfectly fit your brand and product offerings.

4.Types Of Dental Titanium Disc

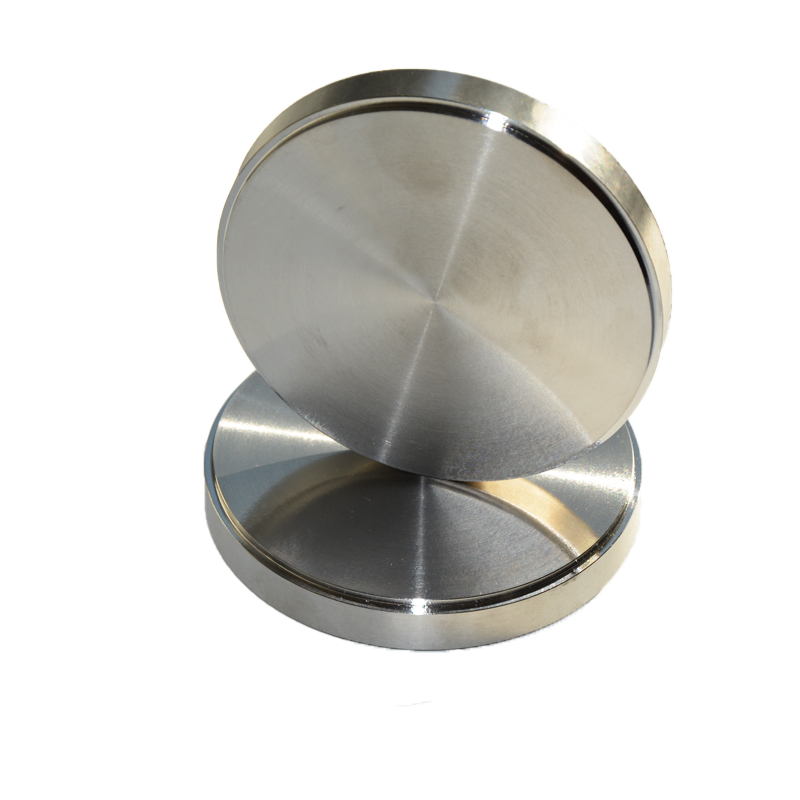

SOLID TITANIUM DISCS

These discs are made entirely of solid titanium and are often used as a base material for milling dental prosthetics, such as crowns and bridges. Solid titanium discs provide strength, durability, and biocompatibility.

TITANIUM ALLOY DISCS

Dental titanium discs can be manufactured using titanium alloys, which are mixtures of titanium with other elements such as aluminum, vanadium, or zirconium. Titanium alloys may offer specific advantages, such as improved mechanical properties or enhanced machinability.

MILLED TITANIUM DISCS

These discs are produced using milling machines that carve out the desired dental restoration from a solid block of titanium or titanium alloy. Milled titanium discs allow for precise and customized designs, ensuring a perfect fit for the patient.

SINTERED TITANIUM DISCS

Sintering involves compacting and heating titanium powder to form a solid mass. Sintered titanium discs are created through this process and are utilized in various dental applications, particularly in the production of complex shapes or structures.

TITANIUM BLANK DISCS

Titanium blanks are pre-formed discs that serve as a starting point for the dental restoration. Dental technicians can then use computer-aided design and computer-aided manufacturing (cad/cam) technology to mill or shape the titanium blank into the final prosthetic.

TITANIUM DISCS FOR IMPLANTS

Specifically designed for dental implant applications, these discs are used in the fabrication of implant components such as abutments and connectors. The ability of titanium to osseointegrate with bone makes it a preferred material for dental implants.

MULTILAYER TITANIUM DISCS

These discs are composed of layers of different materials, often combining a titanium base with layers of aesthetically pleasing ceramics. Multilayer discs allow for the creation of dental restorations that mimic the natural appearance of teeth.

PRE-SHADED TITANIUM DISCS

To simplify the dental laboratory process, pre-shaded titanium discs come in different shades, allowing technicians to choose a disc that closely matches the desired tooth color. This reduces the need for additional coloring or veneering.

.jpg)