How to quickly learn about our dental zirconia blocks

2025-02-11

To quickly familiarize yourself with zirconia blocks used in dental applications, you can follow these steps:

Material Composition: Understand that zirconia blocks are made from zirconium dioxide (ZrO2), a highly durable ceramic material known for its strength and resistance to breakage.

Types of Zirconia

Types of Zirconia: Familiarize yourself with the different types of Zirconia available, such as:

3Y-TZP: Yttria-stabilized tetragonal zirconia polycrystalline, a standard type due to its high strength and toughness. This type is what we usually call HT series, with a permeability of 40%; strength: 1350MPA;

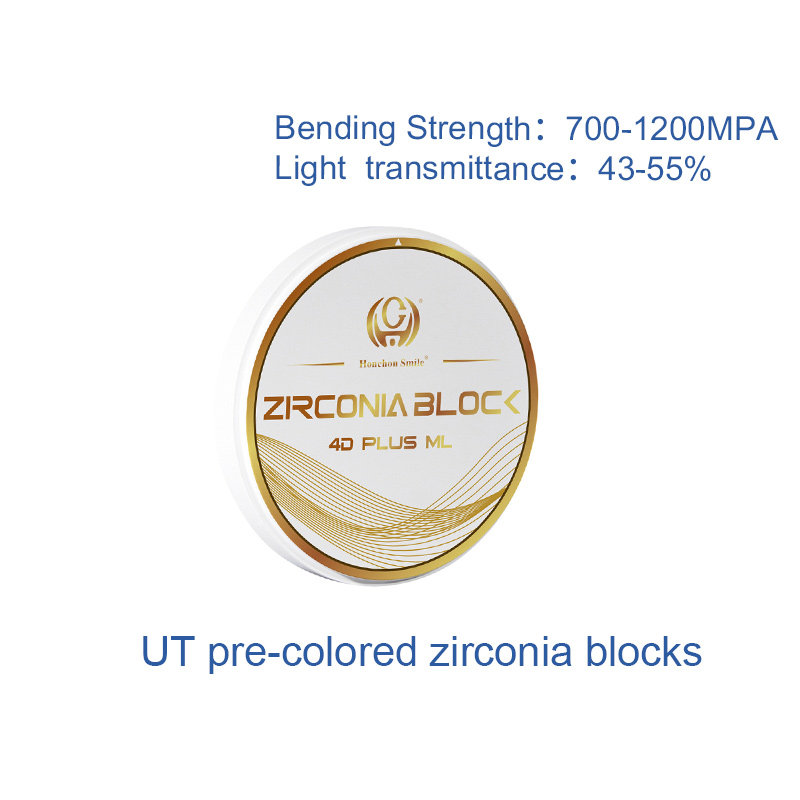

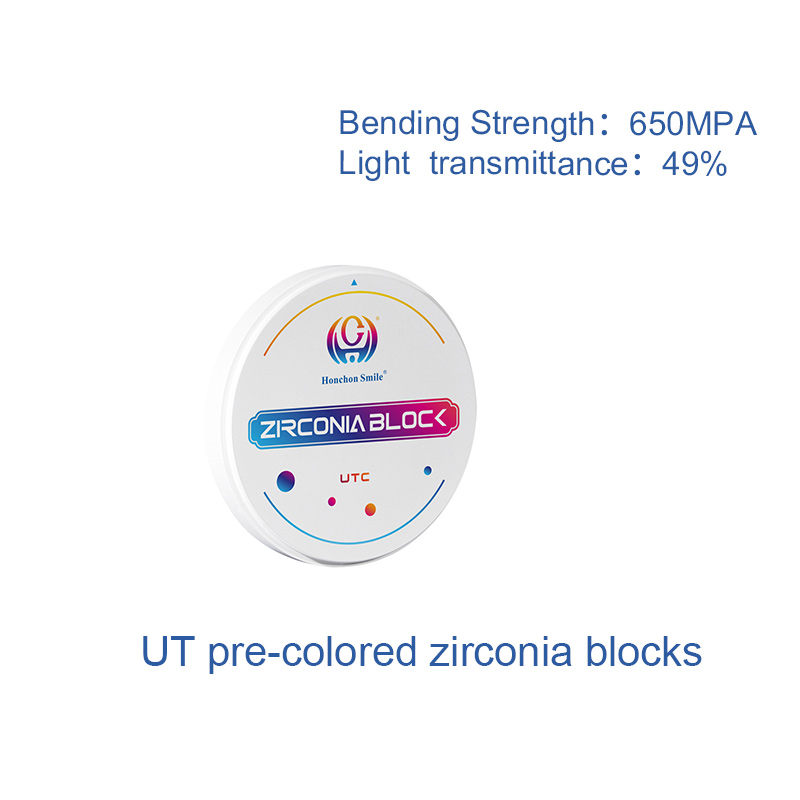

4Y-TZP or 5Y-TZP: These have a higher yttrium oxide content and provide a better balance between translucency and strength. 4Y-TZP is what we usually call ST series, with a permeability of 43%; strength: 1200MPA; 5Y-TZP is what we usually call UT series, with a permeability of 49%; strength: 650MPA;

3Y-4Y-5Y mixed series,4Y-5Y hybrid series": This series is what we usually call multi-layer zirconia series. The entire block has different degrees of translucency and strength, imitating the natural gradient of teeth.

Attributes

Attributes: Understand the main properties of zirconia blocks, including:

High flexural strength and fracture toughness make it suitable for posterior crowns and bridges.

Excellent biocompatibility, reducing the risk of allergic reactions and irritation.

It has good wear resistance and is gentle on natural teeth during chewing.

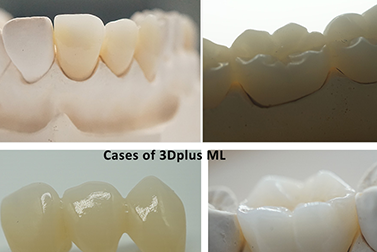

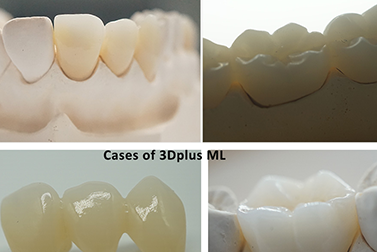

Aesthetics: Please note that while zirconia has excellent strength, earlier versions were less translucent and therefore less aesthetically pleasing. However, newer formulations offer enhanced esthetics and improved translucency, making them suitable for anterior restorations as well.

Manufacturing Processes: Understand the two main manufacturing processes:

Cold Isostatic Pressing (CIP): Creates a uniform density throughout the block, which is ideal for strength.

Pre-sintered blocks: Designed for compatibility with CAD/CAM systems for efficient milling and customization.

Recommended indications

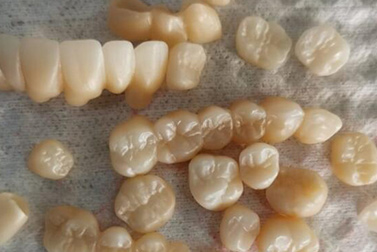

Applications: Learn about the various dental applications of zirconia blocks such as crowns, bridges, veneers, inlays and onlays.

Compatibility: Check the compatibility of zirconia blocks with different dental milling machines and CAD/CAM systems to ensure they can be used within your existing workflow.

Sintering Requirements: Please note that after milling, zirconia restorations often need to be sintered in a high-temperature furnace to achieve final strength and density.

Clinical Studies and Reviews: Look for clinical studies, reviews, and testimonials from other dental professionals about their experiences with specific zirconia blocks and their long-term performance.

If you have any questions about zirconia blocks, you can communicate with us. Our factory already has 10+ production operations, WhatsApp +8613055185196

honchon smile is a professional dental zirconia block manufacturer and supplier. We provide high-quality dental zirconia blocks, multilayer zirconia blocks, pre-colored dental zirconia blocks. Welcome to discuss cooperation with us!