About Zirconia Blocks: An In-Depth Analysis and Comprehensive Guide

2025-06-03

Introduction

Dental zirconia blocks, also known as dental zirconia ceramic blocks, are currently the most widely used dental material on the market. In recent years, zirconia blocks have made significant progress in the field of dental restoration. Their excellent physical and chemical properties make them highly popular among users, such as high translucency, durability, and ease of cleaning, making them an ideal choice for manufacturing high-quality dental restorations. This article will delve into various aspects of dental zirconia blocks, including their definition, characteristics, applications, manufacturing process, selection criteria, and comparisons with other materials.

1. Basic Knowledge of Zirconia Blocks.

1.1 Definition and Characteristics

Zirconia, scientifically known as zirconium dioxide (ZrO₂), is a mineral belonging to the silicate family. It possesses outstanding mechanical properties, including high flexural strength (1400 MPa), high hardness (1200 HV), and a robust Young's modulus (15.84). These properties make zirconia blocks highly effective in dental restorations, capable of withstanding various stresses and wear in the oral environment.

1.2 Evolution and Development

The application of zirconia blocks in the dental field dates back to the late 20th century. Initially, it was primarily used to manufacture zirconia cores for dental crowns, layered with porcelain to achieve an ideal aesthetic effect. With the advent of computer-aided design and computer-aided manufacturing (CAD/CAM) technology, the introduction of all-zirconia restorations marked a significant advancement in the dental field. In recent years, the emergence of colored multi-layer zirconia blocks and high-transparency zirconia blocks has further driven the development of aesthetic dentistry.

2. Wide Applications of Zirconia Blocks

2.1 Dental Applications

Zirconia blocks play a pivotal role in dental restorations. They are used to manufacture various dental prosthetics, such as crowns, bridges, and implant abutments. The high strength, biocompatibility, and natural appearance of zirconia blocks make them an indispensable material in dental treatments.

2.2 Applications in Other Industries

Beyond the dental field, zirconia blocks are widely used in industries such as ceramics and glass manufacturing, aerospace and defense, biomedical and healthcare, and foundry and refractory materials. Their versatility, strength, high-temperature resistance, biocompatibility, and electrical properties make them highly valuable across various industries.

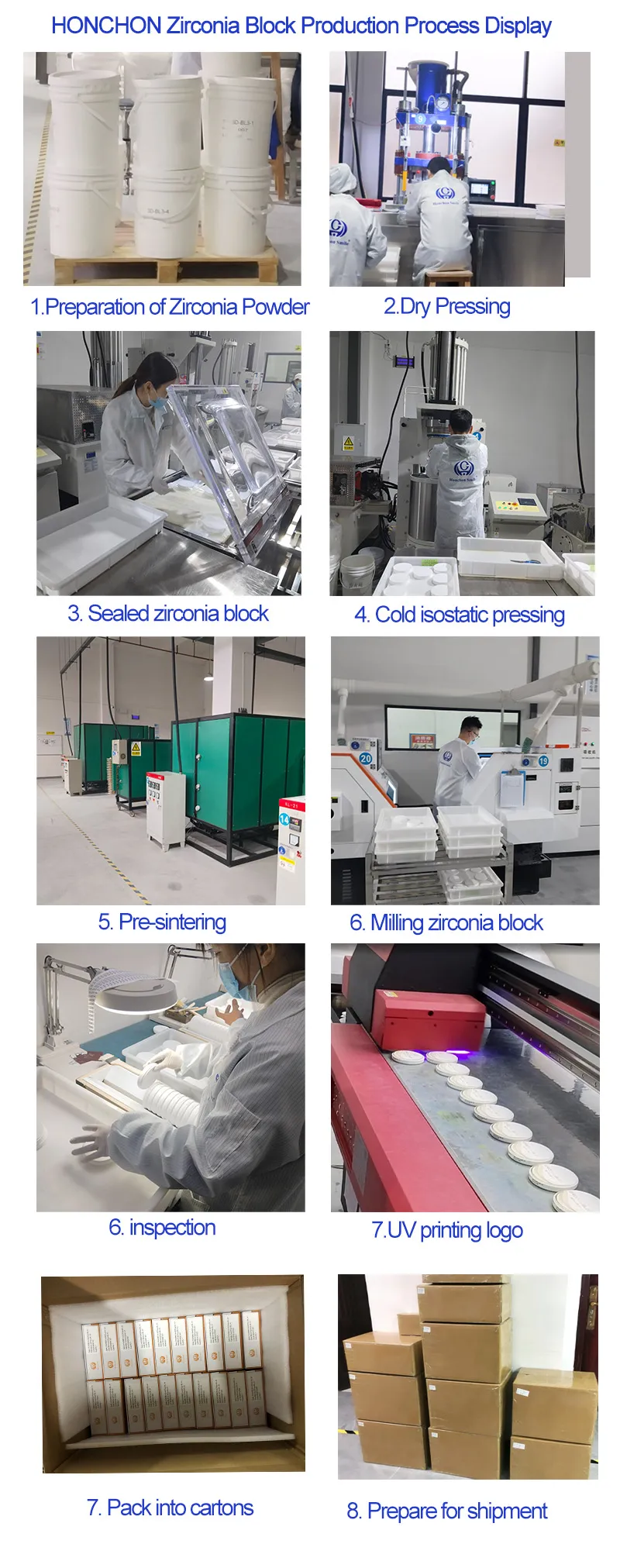

3. The Manufacturing Process of Zirconia Blocks

3.1 Raw Material Selection and Preparation

The production of zirconia blocks begins with the careful selection of high-quality zirconium ore. The selected ore undergoes a rigorous purification process to remove impurities, ensuring the purity of zirconium. Subsequently, the purified zirconium reacts with oxygen to form zirconium dioxide (ZrO₂), the basic component of zirconia blocks.

3.2 Powder Preparation and Isostatic Pressing

Zirconium dioxide is processed into fine powder, ensuring uniform particle size and distribution. A stabilizer (typically yttrium oxide Y₂O₃) is then added to the zirconium oxide powder to enhance its stability and prevent phase transformation. The powder mixture is then placed into a rubber mold for isostatic pressing, where uniform pressure is applied from all directions to compress it into a dense green body.

3.3 Pre-sintering and CAD/CAM Milling

The green body is pre-sintered at moderate temperatures to achieve initial strength while retaining slight porosity to ensure grinding precision. Subsequently, CAD/CAM software based on patient-specific digital impressions is used to digitally design the pre-sintered zirconia block. A precision milling machine carves the zirconia block into the desired dental restoration shape and dimensions with unparalleled accuracy.

3.4 Coloring, Sintering, and Polishing

Before final sintering, the milled restorations can be colored using specialized coloring solutions to enhance aesthetics. The restorations then undergo a high-temperature sintering process in a furnace, significantly increasing the hardness and density of the zirconia. Finally, a meticulous glazing and polishing process provides a smooth surface to minimize plaque accumulation.

4. Specific Applications of Zirconia Blocks in Dentistry

4.1 Crowns and Bridges

Zirconia crowns are renowned for their exceptional strength and durability, making them ideal for restoring damaged or weakened teeth. Additionally, zirconia bridges effectively replace one or more missing teeth, providing stability and functionality.

4.2 Implant Abutments

Zirconia is commonly used for implant abutments, serving as the connecting component between the implant and the artificial tooth. Its biocompatibility and aesthetic properties make it the optimal choice for creating natural and durable abutments.

4.3 Veneers, Inlays, and Onlays

Although zirconia veneers are less common than porcelain veneers, they remain a viable option for improving tooth aesthetics. Additionally, zirconia can be precisely milled to create inlays and onlays for indirect restorations treating cavities or structural damage.

4.4 Full Arch Restorations

Zirconia blocks are also used to fabricate full arch restorations for patients requiring complete replacement of upper or lower teeth. Their high strength ensures the longevity and stability of these comprehensive restorations.

5. How to Select the Optimal Dental Zirconia Block

5.1 Biocompatibility

Biocompatibility is the primary consideration when selecting dental zirconia blocks. Excellent biocompatibility minimizes the risk of oral adverse reactions or inflammation and promotes healthy gingival tissue around the restoration.

5.2 Mechanical Properties

Depending on the restoration location, selecting zirconia blocks with different strengths and translucency is critical. For example, posterior tooth restorations typically require higher-strength zirconia blocks, while anterior tooth restorations prioritize aesthetic appeal.

5.3 Aesthetics

Aesthetics are particularly important for anterior tooth restorations. Selecting zirconia blocks with high translucency and natural color can achieve realistic aesthetic results.

5.4 Dental Preparation Requirements

Zirconia restorations typically require minimal tooth reduction to preserve more natural tooth structure. Therefore, when selecting zirconia blocks, it is also important to consider their requirements for dental preparation.

5.5 Longevity and Cost

High-quality zirconia blocks offer long-term reliability, but they also come at a higher cost. Therefore, when making a selection, it is essential to consider the patient's needs, budget, and long-term outcomes comprehensively.

5.6 Dentist's Skills

The success of zirconia restorations also depends on the dentist's expertise in treatment planning and bonding. Therefore, when selecting zirconia blocks, the dentist's skills and experience must also be considered.

6. Differences Between Types of Zirconia Blocks

6.1 Multi-Layer Zirconia Blocks

Multi-layer zirconia blocks feature layers of varying colors and translucency, simulating the transition from enamel to dentin and replicating the natural gradient of teeth. These blocks are primarily used for anterior tooth restorations, providing a lifelike appearance.

6.2 White Zirconia Blocks

White zirconia blocks, also known as monolithic or colorless zirconia blocks, are made from uniformly colored, high-purity white zirconia. They offer excellent strength and durability, making them an ideal choice for posterior crowns or bridges.

6.3 Colored Zirconia Blocks

Colored zirconia blocks are pre-colored during production to match various natural tooth shades. They provide a harmonious blend of aesthetics and strength, suitable for restorations requiring precise tooth shade matching.

7. Comparison of Zirconia Materials with Other Materials

7.1 Aesthetic Comparison

Compared to metal ceramics, zirconia offers superior translucency and color matching capabilities. It seamlessly blends with natural tooth colors, eliminating the influence of metal edges and providing a more natural aesthetic effect.

7.2 Biocompatibility Comparison

Zirconia exhibits excellent biocompatibility, being non-toxic and harmless to living tissues. In contrast, the metallic components in metal ceramics may cause allergic reactions or discomfort in some patients.

7.3 CAD/CAM Technology Application

Zirconia restorations benefit from CAD/CAM technology, enabling precise fitting and reducing chair time during adjustments and cementation. This technology enhances the overall efficiency and accuracy of the restoration process.

7.4 Strength and Durability Comparison

Zirconia is renowned for its strength and crack resistance, making it suitable for restorations in high-stress areas. While metal ceramics also possess strength and durability, zirconia outperforms them in these aspects.

7.5 Cost Comparison

Due to differences in material costs and manufacturing processes, zirconia restorations typically cost more than metal ceramic restorations. However, considering zirconia's long-term value and aesthetic appeal, this cost difference is acceptable.

Conclusion

As an important material in modern dental restorations, zirconia blocks have gained widespread recognition for their excellent mechanical properties, biocompatibility, and aesthetic appeal. With ongoing technological advancements and expanding application areas, the future prospects for zirconia blocks in dentistry and other industries are increasingly promising. We look forward to seeing more innovative zirconia products emerge in the future, bringing greater benefits to both patients and practitioners.