Understanding the Different Types of Dental Zirconia Blocks: White, Pre-Shaded, Multilayer, and Gradient Multilayer

2025-07-14

1. White Zirconia Blocks

Overview:

White zirconia blocks are the most basic form of zirconia. They are not pre-colored and require manual staining or dipping before sintering.

Features:

High strength (often 1100–1200 MPa or more)

Requires external coloring liquids

Suitable for posterior crowns, bridges, and frameworks

Best for customized staining based on dentist request

Pros:

Flexible for personalized shading

Often the most cost-effective option

Cons:

Requires extra staining work

Color uniformity depends on technician skill

Price:

$ Most affordable

2. Pre-Shaded Zirconia Blocks

Overview:

Pre-shaded zirconia blocks are infused with color matching standard dental shades (e.g., VITA A1–D4) during production.

Features:

Uniform color throughout the block

Available in various shades (VITA16 + bleach options)

No need for external coloring

Consistent results for single units and small bridges

Pros:

Saves time in the lab

Reduces staining errors

Stable color after sintering

Cons:

No gradient effect—best for monolithic crowns, not anterior restorations

Price:

$$ Moderately priced

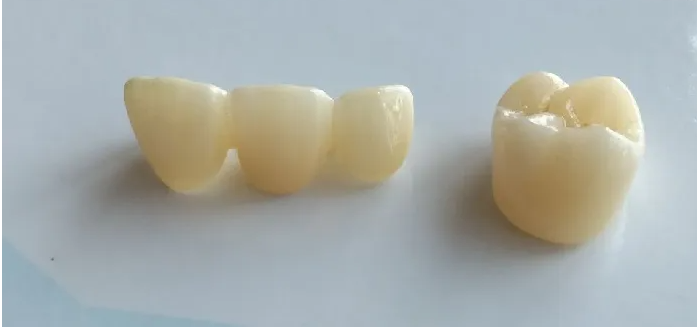

3. Multilayer Zirconia Blocks

Overview:

Multilayer zirconia blocks are engineered with multiple horizontal layers to simulate the natural transition from dentin to enamel.

Features:

Typically 3–5 color layers

Shade and translucency vary across layers

Ideal for full-contour crowns and bridges

No additional staining required

Pros:

Natural aesthetic result

Time-saving

Good strength with decent translucency

Cons:

Limited gradient smoothness (compared to 4D or gradient multilayer types)

Price:

$$$ Higher than pre-shaded blocks

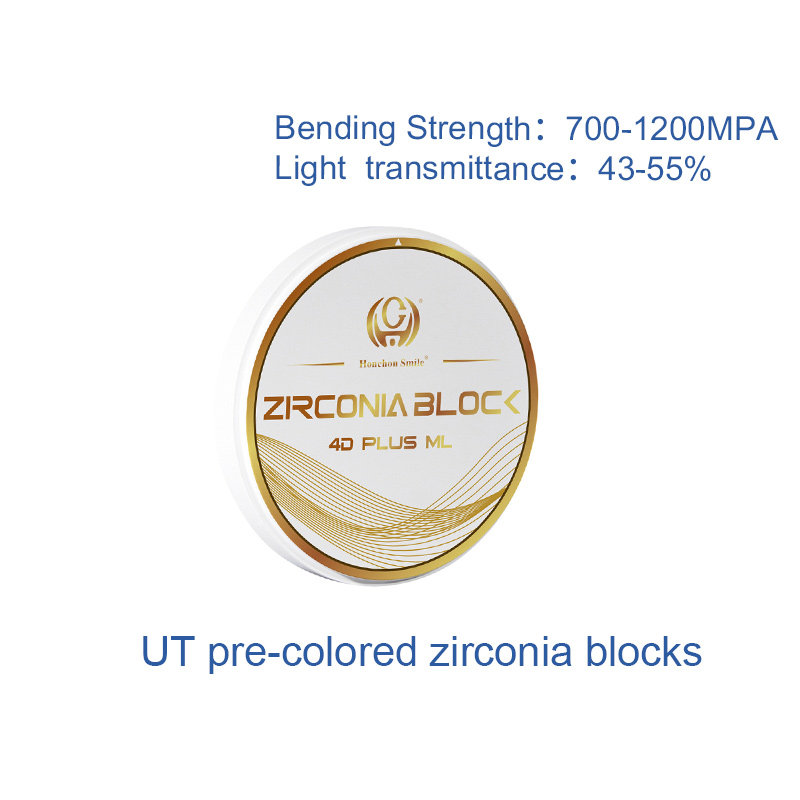

4. Gradient Multilayer Zirconia Blocks (Also Known as 4D or 5D Zirconia)

Overview:

These are the most advanced zirconia blocks available, offering a seamless gradient in both color and translucency, mimicking real teeth from cervical to incisal edge.

Features:

Gradual transition in both chroma and translucency

High aesthetics, especially for anterior restorations

Suitable for monolithic full-arch restorations

Often made with premium raw materials (e.g., Tosoh zirconia powder)

Pros:

Most lifelike appearance

No need for extra coloring or veneering

Excellent translucency in incisal zones

Cons:

Highest price point

Slightly lower flexural strength in incisal layer (due to higher translucency)

Price:

$$$$ Most expensive

Summary Table

| Type | Color Treatment | Layers | Translucency | Strength | Price Level | Best For |

|---|---|---|---|---|---|---|

| White Zirconia | External staining | Single color | Low–Medium | Very High | $ | Posterior crowns, long bridges |

| Pre-Shaded Zirconia | Factory-stained | Single color | Medium | High | $$ | Posterior crowns, small bridges |

| Multilayer Zirconia | Factory-stained | 3–5 layers | Medium–High | High | $$$ | Anterior/posterior monolithic cases |

| Gradient Multilayer Zirconia | Factory gradient | Seamless layers | High | Balanced | $$$$ | Full-contour aesthetic restorations |

Conclusion

Choosing the right dental zirconia block depends on the restoration type, location in the mouth, aesthetic requirements, and budget.

White zirconia is cost-effective and ideal for labs that prefer manual shading.

Pre-shaded zirconia balances cost and simplicity.

Multilayer zirconia offers better esthetics with built-in shades.

Gradient multilayer zirconia provides the highest aesthetic results and is perfect for anterior restorations.

At HONCHON, we manufacture all types of zirconia blocks using premium materials and advanced processing technologies. Whether you need cost-effective white blocks or premium gradient multilayer blocks, we have the solution tailored to your needs.

Contact us today for pricing, samples, or OEM customization support.