How Zirconia Crowns Are Made – Step-by-Step Process & Key Benefits

2025-07-14

1. Introduction: What Is Zirconia in Dentistry?

Zirconia (zirconium dioxide) has become a cornerstone in modern dental restorations due to its exceptional strength, durability, and biocompatibility. Used in dental crowns, bridges, and implant abutments, zirconia offers a metal-free, aesthetic alternative to traditional PFM (porcelain-fused-to-metal) crowns.

As the demand for digitally fabricated, high-performance restorations grows, understanding the zirconia crown manufacturing process becomes essential for dental professionals and patients alike.

2. Why Choose Zirconia Dental Restorations?

Zirconia restorations offer numerous advantages that make them a preferred choice in digital dentistry:

High Strength & Durability

Zirconia can withstand chewing forces of up to 1200 MPa, making it ideal for posterior crowns and patients with bruxism.

Natural-Looking Aesthetics

Multilayer zirconia blocks offer color gradients that mimic enamel and dentin, providing a lifelike appearance without porcelain layering.

Biocompatibility

Zirconia is hypoallergenic, non-metallic, and gentle on soft tissues, making it suitable for patients with metal allergies.

Long-Term Wear Resistance

Its hardness and chemical stability ensure a long service life with minimal wear, discoloration, or corrosion.

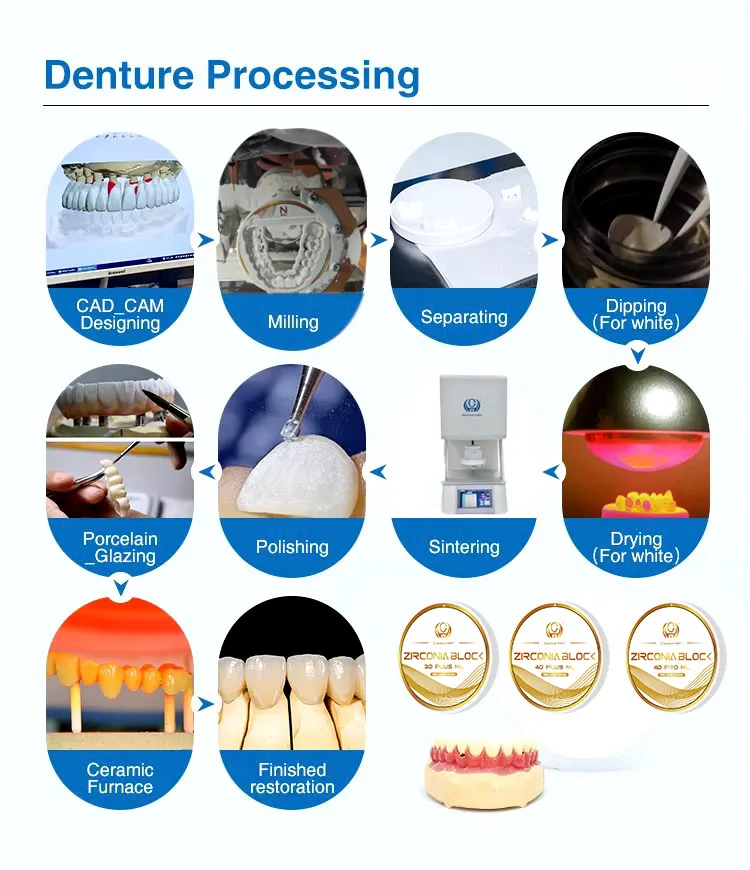

3. Zirconia Crown Manufacturing Process (Step-by-Step)

The zirconia fabrication process combines digital precision with high-performance materials to produce restorations that are both functional and aesthetic.

Step 1: Tooth Preparation

The dentist shapes the patient’s tooth and prepares the margin.

Gingival retraction may be performed to expose the full crown outline.

Step 2: Intraoral Scanning

A 3D intraoral scanner captures accurate digital impressions of the patient’s dentition.

This replaces traditional physical impressions.

Step 3: CAD Design

Using CAD software, a customized restoration is digitally designed based on occlusion, anatomy, and aesthetics.

The technician adjusts the crown thickness, contacts, and fit.

Step 4: CAM Milling

The design is sent to a milling machine to cut the crown from a pre-sintered zirconia block.

Different sizes and shades (white, pre-shaded, multilayer) are selected based on restoration type.

Step 5: Sintering

The milled zirconia crown is placed in a sintering furnace, where it's heated at 1350–1530°C.

This process densifies the crown, enhancing its strength and translucency.

Step 6: Try-In and Cementation

The crown is tried on, checked for fit and occlusion.

After adjustments, it’s polished or glazed and permanently bonded using dental cement.

4. Digital Workflow Benefits in Zirconia Fabrication

| Step | Benefits |

|---|---|

| Digital Scanning | Accurate 3D data, faster turnaround |

| CAD Design | Custom fit, aesthetic control |

| CAM Milling | Precision cutting, reproducible quality |

| Sintering | Superior strength, improved translucency |

The digital process ensures greater consistency, fewer remakes, and better patient outcomes.

5. Future Trends in Zirconia Dental Technology

The zirconia industry continues to evolve, with innovations including:

Ultra-translucent zirconia for anterior aesthetics

Multilayer gradient blocks for faster fabrication

Hybrid zirconia-resin blocks

Integration with 3D printing and AI-assisted design

These advancements aim to enhance mechanical properties, reduce chairside time, and improve esthetic outcomes.

6. Explore Zirconia Blanks for Your Dental Lab

Looking for reliable, cost-effective zirconia materials?

HONCHON offers a full line of white, pre-shaded, and multilayer zirconia blocks compatible with open CAD/CAM systems. All products are:

CE, FDA, ISO 13485 certified

In-stock and ready to ship

Backed by expert technical support

View Dental Zirconia Blocks Product Page

7. Conclusion

Zirconia dental restorations represent the future of high-performance restorative dentistry. With unmatched strength, natural aesthetics, and digital integration, zirconia crowns provide a long-lasting, patient-friendly solution for both clinicians and dental technicians.

Want to learn more or request a quote? Contact us here »

8.FAQ

Q1: How long do zirconia crowns last?

A: With proper care, zirconia crowns can last 10–15 years or more.

Q2: Is zirconia better than porcelain?

A: Zirconia is stronger and more durable than porcelain, while modern zirconia types offer improved translucency for aesthetics.

Q3: Can zirconia be used for full-mouth restoration?

A: Yes, especially multilayer zirconia is ideal for full-arch restorations due to its balance of strength and beauty.